Contact Caswick

Need assistance? Email Caswick | Office Phone: +44(0) 1427 872017

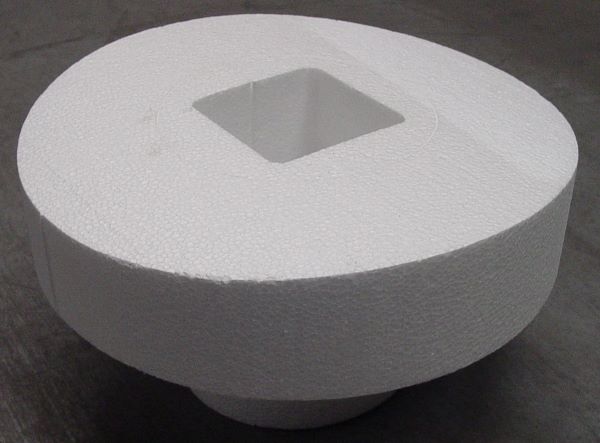

Bespoke Polystyrene Profile Cutting

Caswick can cut formers to your specific concrete product design.

Key Features

- Using polystyrene formwork reduces operator strain through drilling, cutting or coring, improves accuracy over hand working products and reduces wasted concrete

- 3-axis and 4-axis hot wire cutters create your profiles accurately and repeatably from expanded polystyrene

- No tooling costs and computer controlled automated production mean that we can produce 1 off parts or 1000off parts economically

- Parts can be cut up to 2440mm x 1220mm x 610mm in size

- Parts can be assembled into larger or more complex shapes

- Clean polystyrene can be recycled locally

Polystyrene Channel Cutting Machine

The Caswick polystyrene channel cutting machine hot wire cuts straight and curved channels to your specific profile and shape. The machine can also cut shapes such as round tubes using a straight wire. More complicated profiles can be made using a milling spindle.

Key Features

- Channel cutting using pre-formed, rigid, hot wire cutting tools to create your chosen profile. Typically for manhole bases these are a half pipe profile but they can be of any profile you choose.

- Wires are easily formed on site from coils for your chosen profile and loaded into a tool rack for the machine.

- The depth of the channel can be to your choice meaning that you can make half pipe or level invert connections.

- Straight shapes can be cut using a hot wire. These can be any shape and include tapers.