Progressive Box Culvert 1

Box Culvert End Product400

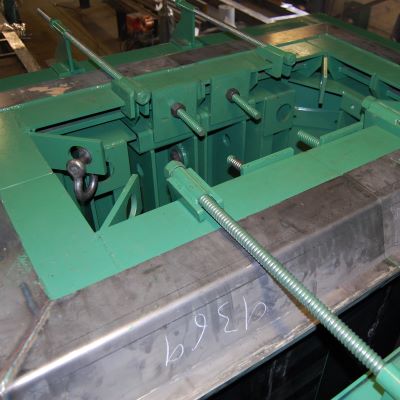

BoxCulvert_1400

Progressive Box Culvert Form 2

BoxCulvert_close400

Afinitas offers a wide variety of box culvert forming systems designed for small bridge, water conveyance and retention applications from well-known, trusted brands like New Hampton Metal Fabrication and Spillman Form.

Whether your application requires individual forms or a fully adjustable system, Afinitas can build a solution in the configuration, size, span and rise combination you need. Our expert engineers will gladly develop box culvert forms to your custom specifications using existing formwork from other manufacturers, saving you time and money.

Learn more about the box culvert forming systems and the products offered by Afinitas.

As most municipal and manufacturing experts know, culverts are drainage systems that exist underneath roads, bridges and other forms of transportation infrastructure to allow for water to flow freely underneath.

Box culverts, also known as four sided concrete culverts, are incredibly versatile formed concrete products suitable for use in retrofit projects, in places like tunnels, underneath bridges, subways, storage facilities and more.

For manufacturers of precast culvert forms, a box culvert formwork system is necessary to craft quality box culverts that fit unique project specifications.

Box culverts are made from reinforced concrete. The biggest problem contractors have with installing box culverts versus other culvert installation such as piping is that concrete cannot be installed in a wet area, as culverts are often installed over rivers, dams and lakes.

Because of this, concrete culverts must be precast, and installed in place once concrete has fully dried.

Box culverts are incredibly economical and provide a solid foundation to support above ground structures such as roads.

With Afinitas box culvert forming equipment, you’ll find features including:

NextGen Box Culvert Forming Systems

Our NextGen systems have the same form quality and life span as our traditional forms, but their streamlined design reduces the floor space needed by approx. 35%. Our NextGen Box Culvert design features include:

@Afinitas