Did you know CurePak can heat aggregates and save you money! Learn more.

At Afinitas our mission is to provide producers with all the tools and expertise necessary for success. In many markets, a key to the production of the highest-quality concrete products is to ensure the products being produced are able to cure in a heat and humidity-controlled environment.

That’s why we developed our SmartSet Curing Systems that will ensure the proper hydration of the cement and result in the strongest concrete possible. Our SmartSet Systems include:

- CurePak direct-fired steam generators for concrete curing (advanced and basic models)

- Kiln control systems

- Air circulation and exhaust systems

- Installation and turnkey services

- Misting and dry burners

- Drying systems

- Piping and equipment installation

- Kilns

- Moving floors

- Retrofits and upgrades

- Troubleshooting and preventative maintenance

- Vast parts inventory

- Dedicated technical team and service vans

CurePak Is Now Part of the Afinitas SmartSet Curing Offering

Industries Served

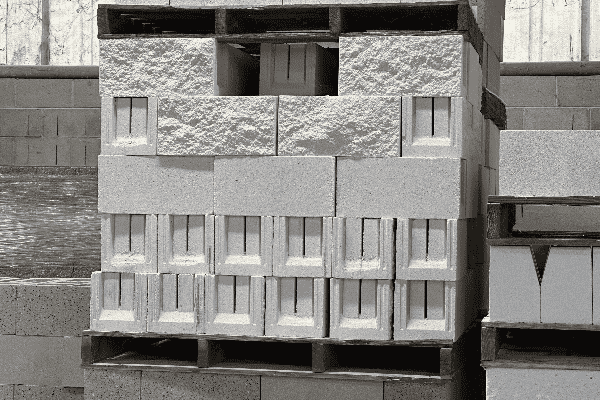

Block

Precast

Prestressed

Pipe

Roof Tile

System Features

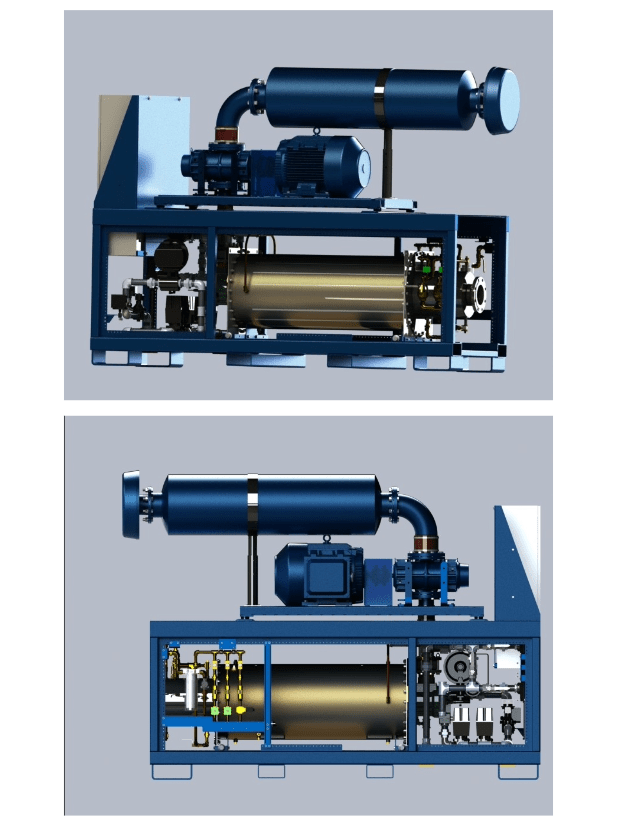

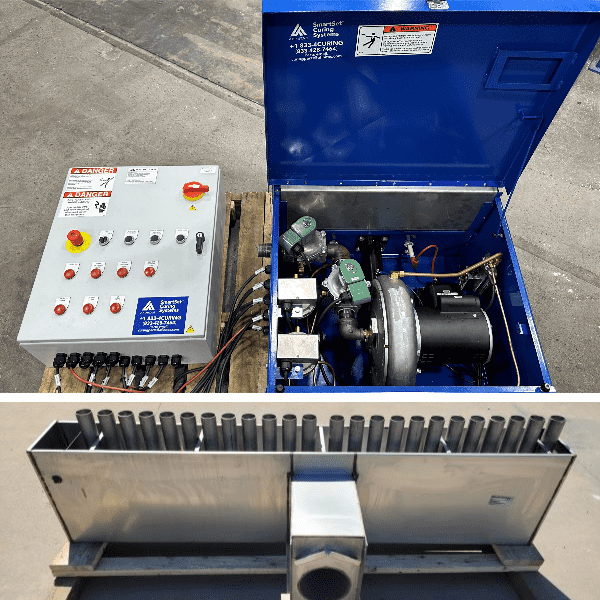

Direct-Fired Curing Systems

Reliable and robust direct-fired steam generators are capable of producing large volumes of controllable, low-cost steam – instantly. Operating at half the cost of traditional boilers, Return On Investment (ROI) can be achieved in two years or less, adding profits to your bottom line.

Benefits of Steam Generation:

Reduced Operating Costs – uses half the gas and water required for boilers

Increased Production – produces instant steam for nearly 100% thermal efficiency

Reliable Performance – operates efficiently and dependably

Worker Safety – combustion occurs before water can contact hot air, minimizing the risk of carbon monoxide production

Flexible Curing Parameters – ideal for jobs requiring both intermittent and continuous steam production

Available in a high pressure version, up to a maximum of 10 PSI at 3 MMBTUH

Reliable Operation

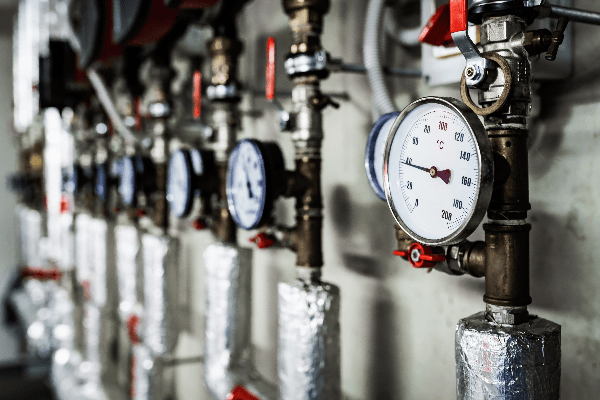

Operators or automatic controls are continuously changing which valves are open and shut to curing areas to meet production requirements. This changes the load needed for the curing system. SmartSet™ adjusts the firing rate for the curing load automatically to cure your product efficiently and maintain proper temperature control. It automatically adjusts the burner to compensate for upstream changes in water pressure changes.

Automated Temperature Control

The accurate control of SmartSet’s outlet temperature is critical to curing a wide variety of concrete products. A very small change in the water flow results in a large change in outlet temperature. Our system automatically anticipates thermocouple reaction time during outlet temperature changes. SmartSet™ also automatically compensates for any changes in upstream water pressures or water delivery.

• Ensures accurate viable control over the quality of the cure steam

• Avoids head losses caused by excess water common in low output-temperature curing systems

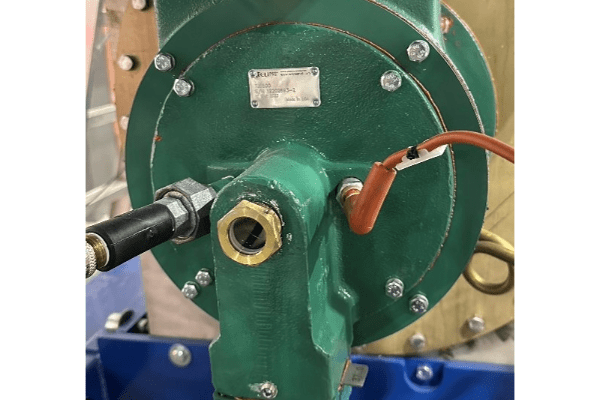

Combustion-Engineered Burner

The heart of the combustion system is the precision burner assembly. The burner is engineered to provide positive flame propagation and flame retention under a wide variety of gas/air ratios and line pressures. Because of this, SmartSet™ starts and burns consistently under varying operating pressures.

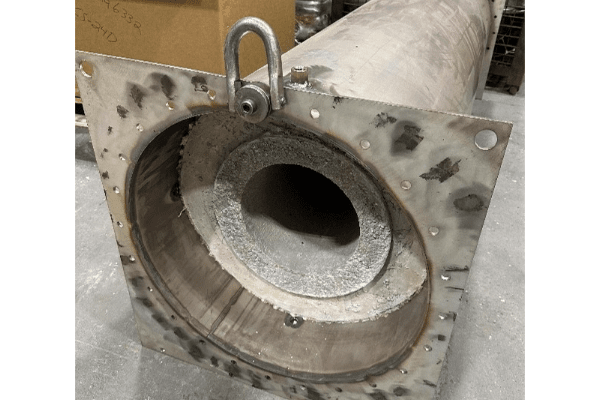

Large Combustion Chamber

The chamber provides the three “T’s” of proper combustion:

TIME, TEMPERATURE and TURBULENCE:

• Large enough to provide the TIME to ensure completion of combustion prior to the introduction of water.

• Lined with refractory, this assures flame TEMPERATURE for proper combustion.

• Produces the desired TURBULENCE for a clean burn.

Auto Fog Control Panel System

This kiln control panel is designed to “steam” and “hold” a kiln to a selected target temperature, or to intermittently “fog” a kiln. It also has the logic for intermittent control of a misting system. It can do any of these three functions during each “PRE-SET” or “CURE” cycle. A dual setpoint temperature controller displays and controls the kiln temperature during each cycle if the “steam” option is selected.

If “FOG” or “MIST” is selected, the on and delay times are programmable to achieve a desired kiln humidity for weekend or “hot summer day” curing.

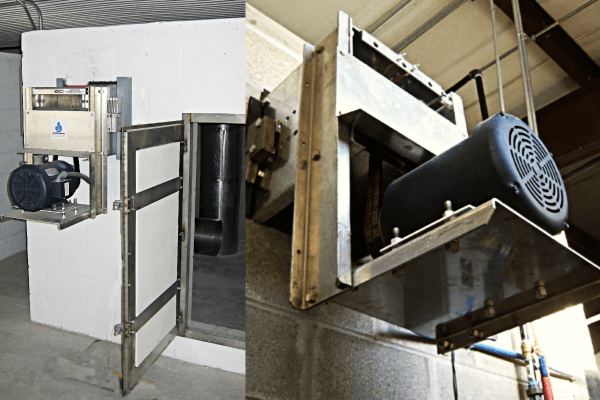

Circulation System

Our revolutionary circulation system creates even circulation of heat and moisture throughout the kiln which ensures that every pipe is properly cured to achieve optimal strength.

The accurate control of the CurePak’s outlet temperature is critical to curing a wide variety of concrete products. A very small change in the water flow results in a large change in outlet temperature. Our control system automatically anticipates thermocouple reaction time during outlet temperature changes. The system also automatically compensates for any changes in upstream water pressures or water delivery.

This exclusive outlet temperature control system assures accurate variable control over the quality of the cure steam and avoids the heat losses caused by excess water common in low-output-temperature curing systems.

Drying for Block Systems

When your customer requires product that is classified as dry block, our drying system is the solution you need. The depth of dryness is determined by the amount of time the block is dried. As a component of our overall curing system, this versatile dryer can achieve optimal surface dryness without re-handling the block to move it into a separate drying system.

Alternatively, our dryer can be used as a standalone system. It is ideal for producing block that is going to be treated with an epoxy coating, ensuring a perfectly dry surface for optimal bonding properties.

Misting System

Our misting system ensures that your product stays moist before curing. We offer multiple types of misters, based on how much automation and ease of maintenance your process requires.

A Series Burner System

This unique curing system is comprised of a wide variety of solutions that can be customized for any concrete product. We start with our proven burner and add the components that best fit your product and curing requirements.

For example, our equipment for block production is designed with our A-series burner, an A-series vaporizer, fog control system, circulation system and misting system. It can also be equipped with an exhaust system to eliminate moisture from the kiln before it is opened, to prevent it from being released into your plant.

Our A Series System can also be equipped with a fog kiln control panel. During summer or in a desert climate when a reduced amount of energy is needed for curing, you still need the right amount of moisture during the precast step to avoid spider cracks that can occur when the pipe gets too dry. The fog kiln control panel allows you to easily adjust time and temperature parameters to ensure the highest product strength possible.

Kiln Systems

Canopy Kiln Curing System

The traditional solution to the curing of concrete pipe, manhole and box culverts is the Canopy Kiln System. Utilized in hundreds of factories, the Canopy Kiln System is economical, functional and extremely flexible in that it can be adapted to any type of building or arrangement. Manually operated, the Canopy Kiln is simple to use and even simpler to maintain, with minimal moving and wearing parts. The Canopy Kiln System folds up against the kiln wall throughout the production process, and when the kilns are full, the overhead crane is used to deploy the curtains and cover the concrete pipes, at which point steam may or may not be introduced into the system, depending on the wishes of the producer or the local climate. Look to HawkeyePedershaab and BFS Canopy Kiln Curing Systems for equipment that is:

- Economical

- Simple to operate

- Simple to maintain

- Adaptable to any plant layout

Telekiln Curing Systems

The TeleKiln is an accordion-style curtain kiln system that advances over the concrete products in the kiln as they are produced, covering them and keeping the wind and external environment from affecting the curing process. This system is especially popular in warm, windy climates where the ambient temperature necessitates the opening of plant doors, allowing winds to blow across the products in the kilns, drying them out and preventing proper curing. Telekiln can be remote-controlled and includes an optional misting system to keep the concrete products properly hydrated. The system also has the added benefit of operating without tying up the plant’s overhead crane. HawkeyePedershaab and BFS Telekiln curing systems are know for:

- Immediately covering the pipe

- Automatic misting system

- Remote-controlled operation

- Adaptability to any plant layout

Autokiln Curing Systems

The AutoKiln Curing System represents the most advanced concrete pipe and manhole curing system in the marketplace. Tailored to work in conjunction with a moving-floor automatic factory, AutoKiln allows for precise, zoned, computer-controlled manipulation of the temperature and humidity throughout the entire curing process, including pre-cure and post-cure processes. In addition to its ability to fully control the curing process, AutoKiln uses high R-Value, insulated walls and doors to reduce energy usage and prevent corrosive steam or humidity from leaking out of the system and affecting the rest of the factory. Trust HawkeyePedershaab and BFS Autokiln Curing solutions for:

- Allowing 24-hour continuous production

- Complete control of the curing process

- Independent temperature and humidity control

- Fully automatic operation

Concrete Curing Services

One-Stop Curing Resource

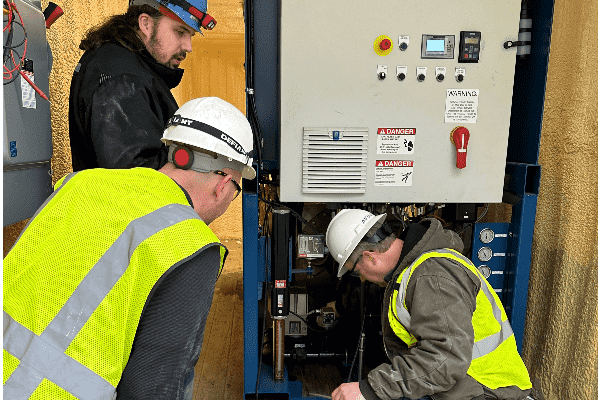

At Afinitas our goal is to ensure you that you have the curing solutions that are best suited to your needs to produce durable, quality products with high efficiency and minimal downtime. Our skilled technicians are available to assist onsite, by phone or via remote-in technology to troubleshoot, repair, install, consult and provide guidance on the most effective curing processes.

Technical Support and Training

We are proud to have some of the industry’s foremost curing experts on our team. Combined they have decades of experience and have assisted customers worldwide with curing solutions. If you have an existing system or are interested in a completely new system, you can count on their advice to ensure your systems are running safely and efficiently.

And once your system is up and running, our service program is just beginning. We are there to assist with technical guidance, documentation and instruction for your curing operations teams and ongoing support throughout the life of your system.

Installation/Turnkey Services

Retrofit

We know that curing is critical to your concrete product production and having the right equipment for your specific applications is key. In many cases, a cost-effective way to optimize performance is to upgrade your existing equipment. At Afinitas, we have the engineering expertise to consult on any upgrade. After an extensive review of your facility’s equipment, our team will develop a comprehensive plan that will allow you to extend the life of your existing equipment while making it more efficient. Many times, a retrofit can be done at a fraction of the cost of purchasing new equipment and in a much shorter timeframe.

Retrofit program includes:

- Engineering services

- Modifications on existing systems

- Integration of controls systems, piping, moving floors

- Training and documentation

Repairs

No matter what type of system you have, at some point you will experience a break down due to wear and tear, age, dirt, or lack of proper maintenance. When this happens and your system is down, you need a technician who can quickly identify the problem and have the parts in-stock to fix it. That’s where our onsite service van program comes in.

Our 24-ft., fully stocked service van will come onsite and quickly provide the parts and services to get you back up and running quickly.

Our Repair program includes:

- Technical service

- Repair service

- Spart parts

- Replacement parts

Start Up Service

For new plants or those producers simply looking to enhance operations, we will perform a comprehensive equipment analysis based on the performance metrics you are targeting. Whether a new system is needed or just replacement parts, our goal will be to avoid costly downtime for your plant. Our team of experienced designers and manufacturers of concrete products equipment can provide everything from a direct-fired steam generator to controls, piping, kilns, moving floors and many other parts to ensure you have the perfect curing system for your needs.

Our Replacement Services include:

- Changing out old/outdated equipment

- Custom design new system

- Fully integrate system components

- Configuration, Calibration, Testing

- Training, documentation

Maintain Your Equipment with SmartSet Service Plans

We can help you preserve the life of your curing equipment with our Annual Service/Preventative Maintenance Programs. When you enroll in one of our plans, we’ll make scheduled visits to your site to inspect your equipment and identify parts that are showing signs of wear. While onsite, we will repair/replace them on the spot before they fail and cause unplanned downtime. We also will provide training and technical support.