Afinitas company BFS has been designing and producing quality high pressure concrete pipe equipment for more than 50 years. BFS technology has influenced the development of the pressure pipe production equipment used today worldwide. Therefore, BFS technical specialists are a valuable resource to assist with the design and implementation of complete turnkey plants, from the feasibility studies to the commissioning of the plant. In addition, BFS equipment meets the pipe production requirements of both European requirements (EN) and those of the American Water Works Association (AWWA) and most other rigorous standards for quality. For these reasons, whether you are producing Prestressed Concrete Cylinder Pipes (PCCP Pipes) or Prestressed Concrete Spun Pipes ( PCSP Pipes), BFS expertise helps you manufacture with confidence.

Our Service Never Stops

From the start of the process, BFS is there to help you select the right system to meet your specific requirements. To assist in this, the BFS team provides an initial design of the factory layout as well as pertinent technical and financial details. Once your system has been selected, BFS will manufacture it to your exact specifications and be there every step of the way to ensure it is expertly installed and commissioned. Further, BFS technicians are there for the start up of your production run and provide the training and technical information needed to ensure your operations run smoothly.

Concrete Products

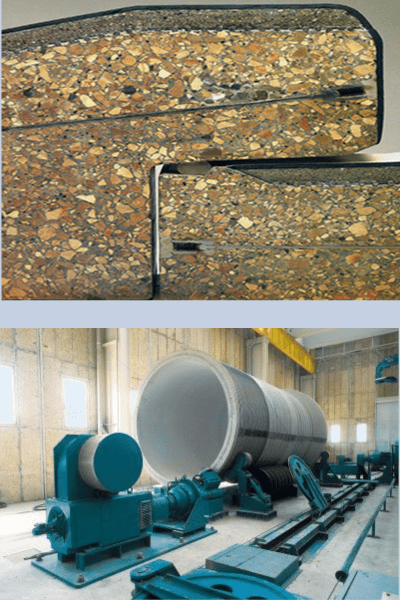

Our BFS high pressure concrete pipe technologies allow you to produce both PCCP and PCSP concrete products.

PCCP Pipe

PCSP Pipe

| Pressure Pipes | Pre-stressed Concrete Cylinder Pipe (PCCP) | Pre-stressed Concrete Spun Pipe (PCSP) |

|---|---|---|

| Normal Nominal Diameters | 400mm up to 4000mm (15" to 150") | 300mm up to 2800mm (12" to 110") |

| Nominal Lengths | up to 8000m (26') | 5000m up to 7000m (16' to 21') |

PCCP Pipes Production

Prestressed Concrete Cylinder Pipes (PCCP)

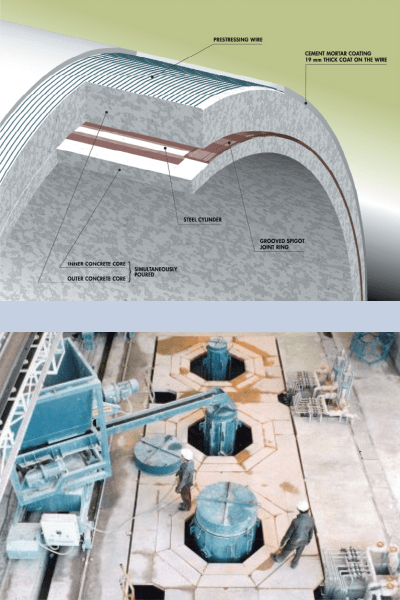

PCCP pipes are mainly manufactured in two different ways:

- PCCP embedded with steel cylinders (ECP)

- PCCP with outer steel cylinders (LCP)

BFS offers a complete line of machines and ancillary equipment for both manufacturing methods. When using the vertical casting process, a steel cylinder is embedded inside the pipe concrete wall. The steel cylinder guarantees impermeability at operating pressures more than 20 bar (290 psi). After steam curing, the core is typically circumferential prestressed using a machine to wind a cold drawn high tensile steel wire and apply high pressure to counteract the operating pressure of the planned pipeline.

PCCP Pipes: BFS Production Equipment Features:

- Specific design of vertical moulds

- Strong and solid mould construction

- Easy hydraulic openings of inner and outer mould

- Concrete distribution by a specifically designed motorized cone

- Strong vibration on the inner and outer mould by means of turbo vibrators

- Clever progressive vibrating system along the mould

- Steam curing for approximately 6 hours inside the casting moulds

- BFS circumferential prestressing machine which is very reliable in maintaining the constant pull and pitch of the steel wire along the entire length of the pipe, guaranteeing an optimal and uniform resistance to pipeline water pressure.

- MRC machine to perform an accurate concrete coating of the post compression steel spiral, preserving it from corrosion

Based on over 50 years of worldwide experience in pressure pipe production systems, the BFS moulds are built with extremely rigid and solid structures, ensuring a long service life of the mould. It is well-know that BFS builds their moulds with the same care that goes into their machines.

Using strong and solid BFS mould construction will benefit your production in two important ways:

- To ensure the geometrical dimensions are maintained during vibration

- To ensure the geometrical dimensions are maintained during the long service life of the mould

Lesser quality moulds such as an elastic mould structure may generate different amplitudes of vibrations in different locations on the mould causing inconsistent vibration of the product.

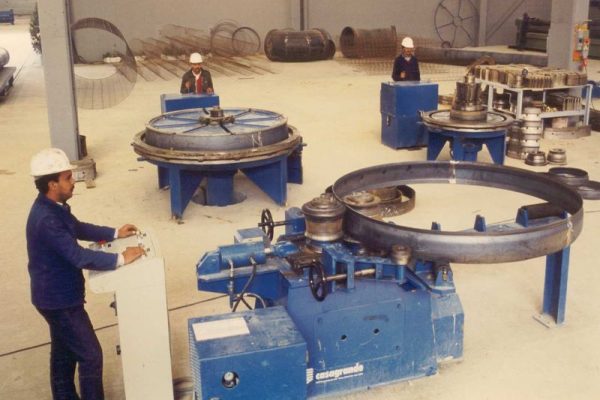

Systems for Prestressed Steel Cylinder Pipes (PCCP):

Main Working Phases

PCSP Production

BFS Prestressed Concrete Spun Pipes (PCSP)

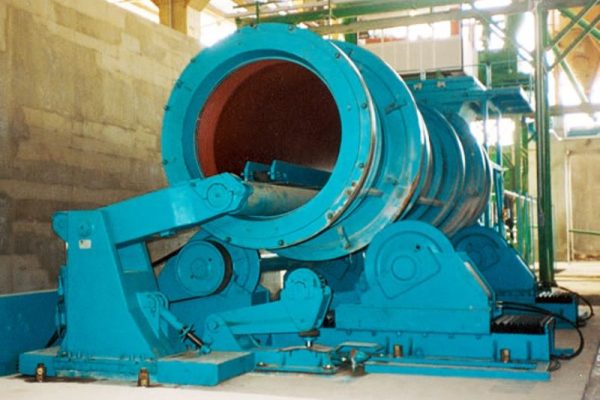

Using BFS Vibro-Press Spinning Technology, BFS prestressed concrete spun pipes are trusted worldwide for their high compaction and concrete density achieved, as well as the reliability of the pipelines using concrete joints.

PCSP Pipes: BFS Production Equipment Features

- Specific design of spun moulds

- Strong and solid mould construction

- High performances of the special BFS spinning machine:

- 30 meters (98′) about per second peripheral speed

- Hydraulic-movable wheels for covering a wide range of diameters

- Special BFS vibration systems (by separated rings) working in the first phase during the concrete pouring process to strongly compact concrete especially at the pipe joints

- The spinning machine’s compacted roller expertly compacts and creates a smooth pipe inner surface

- BFS circumferential prestressing machine: Very reliable in maintaining the constant pull and pitch of the steel wire along the entire length of the pipe, guarantees an optimal and uniform resistance to pipeline water pressure.

- MRC machine to perform an accurate concrete coating of the post compression steel spiral, preserving it from corrosion

- High performances of the spinning machine (30 meters (98′) per second peripheral speed) features hydraulic movable wheels for covering a wide range of diameters and vibrating action on separated rolling rings. The spinning machine’s compacted roller expertly compacts and creates a smooth inner surface.