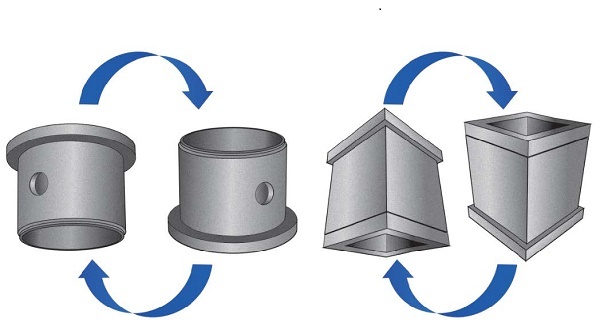

Monolithic precast structures, like manhole bases, catch basins and utility boxes, where the product walls and bases are cast together, create excellent product stability and durability but also come with a few production challenges. Namely, because the product is typically produced upside down and then rotated, the roll-over process can produce dangerous, uncontrollable swinging of the form. This violent swinging can become a major safety hazard, contribute to product and/or equipment damage and also slow down production as it may take several minutes for the product to come to a rest.

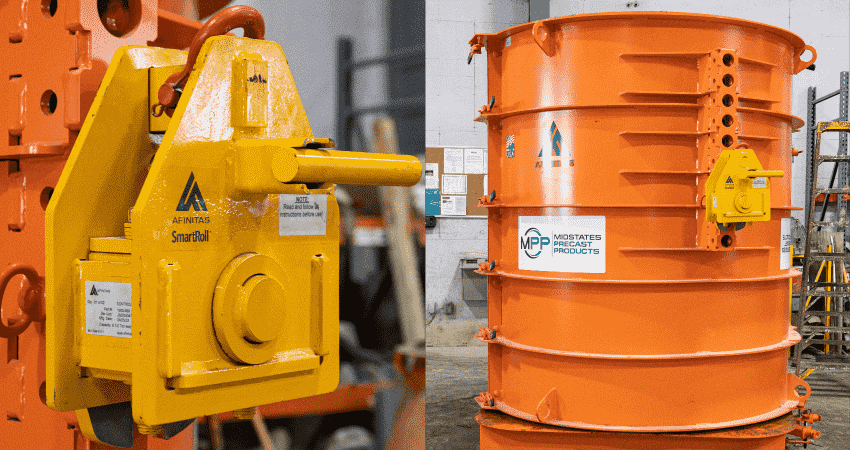

Introducing SmartRoll®

an Intelligent Safety Brake for Controlled Form Roll-Overs

With SmartRoll, you control the roll-over process. Unlike traditional manual methods that utilize form trunnions and crane/hoists to flip the product, sometimes relying on sand piles or similar materials to cushion the roll-over, Afinitas offers an innovative, simple-to-use friction brake system to reduce roll-over speed and momentum. With swinging motions nearly eliminated, operations can be performed faster with fewer safety risks.

Why Choose SmartRoll®?

Reduce the Risk from Form Roll-Overs

Why put your employees or equipment in harm’s way? Our adjustable, friction brake controller is designed to safely reduce the speed of form roll-overs before they become a hazard to employees, form equipment or your production schedule.

Built for Ultimate Control

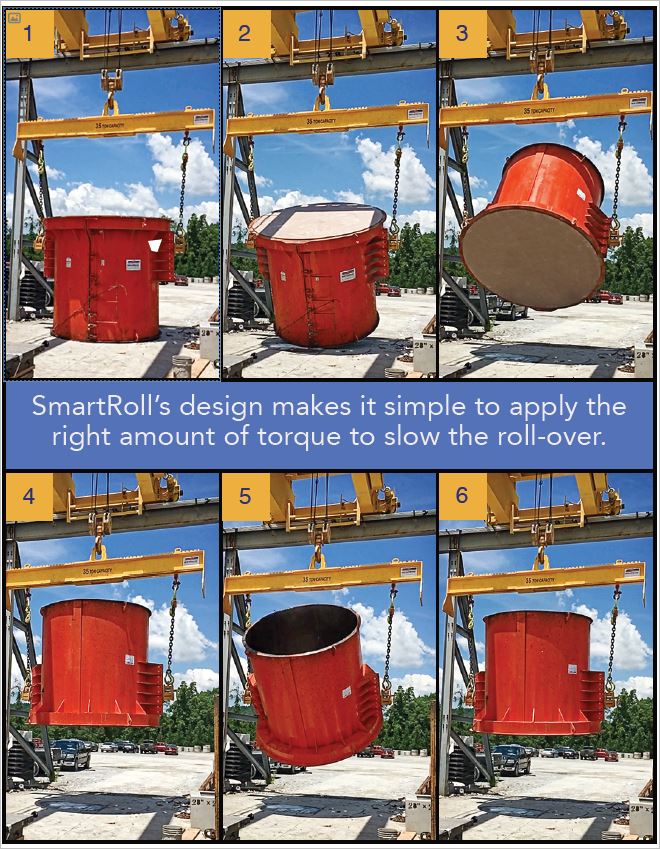

We engineered our controllers with the operator in mind. They are uniquely outfitted with special replaceable urethane inserts that have a high load-bearing capacity making it easy to apply the exact amount of torque required to produce a very consistent and controlled roll-over.

Limit Wear and Save Money

Eliminating the forces of violent roll-overs greatly reduces the stress on your crane equipment and helps prevent damage to your forms saving on repair and replacement costs. Furthermore, our replaceable urethane insert lessens steel-on-steel contact and helps avoid more expensive replacements of trunnion shafts.

In-Stock Selection

We stock the three sizes listed below and their replacement parts.

A SmartRoll brake controller can reduce swinging motion up to 90%!

In Stock and Ready to Roll

| Stocked Sizes | Small Controller Part# 1000-699 | Large Controller Part# 1000-700 | XL Controller Part# PD-HD-0693 |

|---|---|---|---|

| Capacity Each | 13,000 lbs. | 34,000 lbs. | 50,000 lbs. |

| Capacity Set | 26,000 lb.s | 68,000 lbs. | 100,000 lbs. |

| Target Size | Manhole bases 48-72"dia. | Manhole bases 84-96" dia. | Manhole bases 102-144" dia. |

| Target Weight | Product and equipment weighing less than the 13-ton capacity of Small Controllers. | Product and equipment weighing less than the 34-ton capacity of the Large Controllers. | Product and equipment weighing less than the 50-ton capacity of the XL Controllers. |

SmartRoll in Action

Take Control of Form Roll-Overs

- Decrease safety risks

- Reduce costs

- Speed up production with 90% less swinging motion

IMPORTANT: Always consider the dangers when lifting and rolling over product and equipment. Always inspect any lifting device for wear. Afinitas provides a detailed guide to performing safe roll-overs with our controller equipment.

SmartRoll Resources

Increase Production Efficiency with Afinitas Products

Plastic Spacers and Magnets

Afinitas continues to offer the most extensive line of wheel spacers under its Plaswheel® trademark. Plaswheels® are the most universally accepted spacer available as they can be used for both wire mesh and rebar and are molded in a wide variety of covers.

Forming Systems

Afinitas offers unmatched engineering know-how and experience to producers for a wide range of infrastructure applications.

Resources

Access our videos, case studies and brochures to learn more about the products and services the Afinitas Forming Systems Division, which features New Hampton and Spillman brands, provides to the pipe, precast and prestressed concrete market.