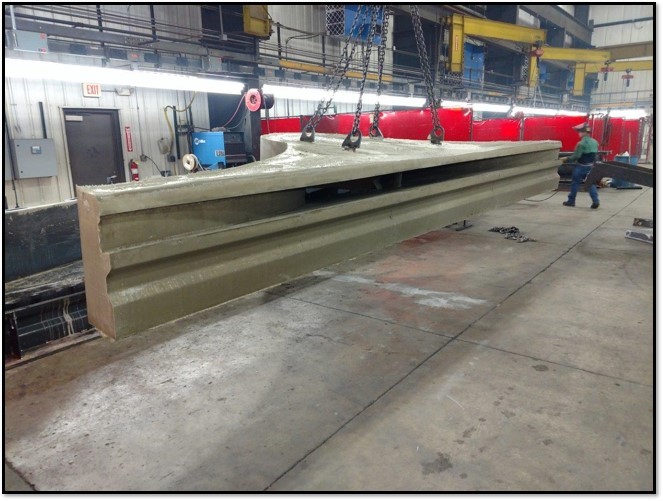

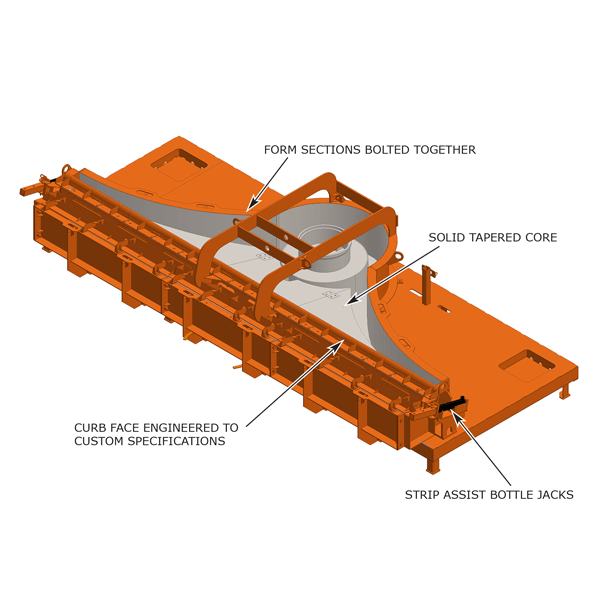

Curb inlets are a critical part of storm water infrastructure that keep communities free from flooding and other safety risks. Clearly, the integrity of these structures is vital and properly engineered forming systems are key. That’s why ours are fabricated from 1/4″ HR steel skin reinforced with 3/8″ and 1/2″ steel channel, ribs and gussets to reinforce material as needed to resist the given loads. Our curb inlet formings systems are available in a wide variety of shapes and sizes to meet your needs. All curb inlet equipment goes through an iron phosphate wash prior to being coated with industrial primer and enamel topcoat paint.

Optional:

@Afinitas