We offer a variety of wire mesh bender machines for single direction, double direction and even a convertible bender option that goes from two benders to one. Known throughout the industry for their quality and capabilities, our benders will provide the shapes and precision angles you need for your precast concrete product production.

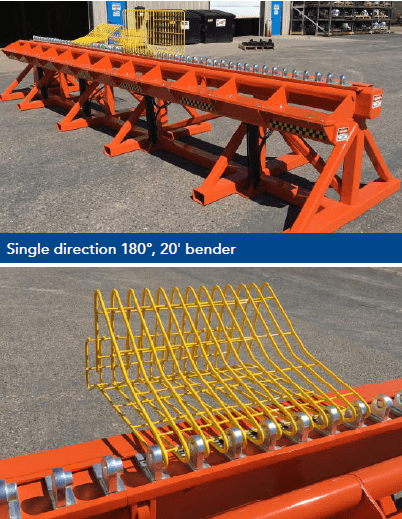

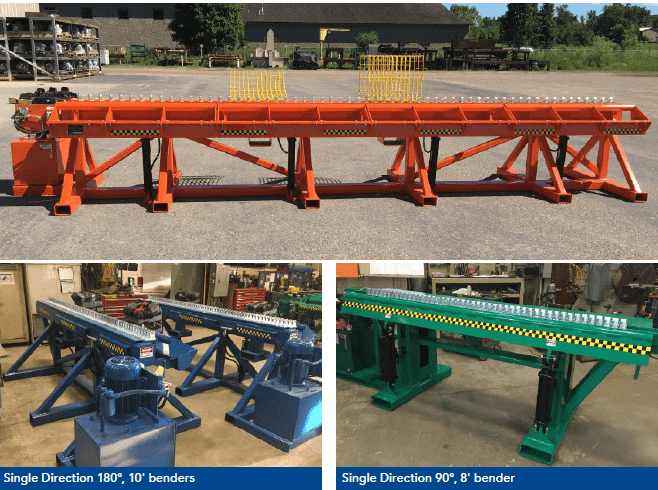

Single Direction Wire Mesh Bender

Standard Features

- Standard units are designed to bend up to D-12.0 on 2″ centers for the entire width of the machine.

- Heavy-duty models are designed and built to bend D-21 on 2″ centers or D-32 on 4″ centers; 180° for a full 30′.

- Bending anvils may be placed individually for variable spaced mesh (radii available from 3/4″ to 3″).

- Single direction benders are furnished with anvils on 4″ spacing (anvils larger than 2.5″and / or additional anvils may be ordered separately).

- Structure, power unit, hydraulic cylinder size and placement design provide accurate and consistent bending.

- Strategically placed hydraulic hoses help prevent misuse and abuse.

- Choice of widths:

- Single direction benders start at 8′ and are available in various lengths

- Single direction 180° benders start at 10′, 20′, and 30′

- Forklift pockets for easy transport.

Technical Capabilities

Single Direction Bender

The Single Direction Benders are equipped with individual bending anvils adjustable to bend variable-spaced mesh. The typical anvil radius furnished with the bender is 3/4″, however, other radii may be furnished by request up to 2.5″. Anvils are furnished at 4″ spacing.

They are convertible to bend mesh to a full 180°. The structure, power unit, hydraulic cylinder size and placement are designed and built to give accurate and

consistent bending.

They have been designed and built to bend D-32 (5/8″ WWR) on 4″ centers for a full thirty feet or D(W)21 on 2″ centers, for a final bend of 180°. Standard sizes – 10′-0″,

20′-0″ and 30′-0 “.

Go From Two Benders to One

With only a slight change-over effort, the single direction 90° bender can be converted to 180° capability. Minimum mesh lead remains at 6″ for 90° bends and approximately 14″ lead for a full 180° operation. Convertible bender widths remain virtually unlimited with 8′ minimum.

Individual bending anvils are mounted in a machined slot, adjustable for variable mesh spacing. The bending arm is easily adjustable for bends up to a

full 180° by simply sliding the plates. Fine adjustments are made by bolted holes located on a radius for variable mesh lead lengths.

Convertible benders include our typical heavy construction with hydraulic cylinders sized and placed appropriately for the bending operation, and mesh size

up to D21(1/2″) on 2″ spacing or D32 (5/8″) on 4″ centers.

Individual bending anvils are mounted in a machined slot, adjustable for variable mesh spacing.

The bending arm is easily adjustable for bends up to a full 180° by simply sliding the plates. Fine adjustments are made by bolted holes located on a radius for

variable mesh lead lengths.

Convertible benders include our typical heavy construction with hydraulic cylinders sized and placed appropriately for the bending operation, and mesh

size up to D21(1/2″) on 2″ spacing or D32 (5/8″) on 4″ centers.