The Multicast can produce virtually any kind of infrastructural product. And we make it simple to do so. The machine’s settings can be easily altered to switch between different dimensions and products – without compromising output or quality. When flexibility is crucial to operations, Multicast is an obvious choice.

Concrete Products

The Multicast can produce almost any infrastructural product, including:

Capacity

Depending on the machine model and configuration and the products being produced, the VIHY Multicast can annually make up to 55,000 tons of products.

Models

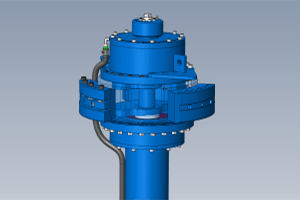

Central Core Vibration Machines

- Multicast SCC 150

- Multicast SCC 200

- Multicast SCC 250

- Multicast XL SCC 300

- Multicast XL SCC 360

Vertical Vibration Machines

- Multicast SCV 120

- Multicast SCV 150

- Multicast SCV 200

- Multicast SCV 250

- Multicast XL SCV 300

- Multicast XL SCV 360

- Multicast XL BC 300

- Multicast XL BC 360

- Multicast XL BC 450

| HawkeyePedershaab VIHY Multicast Central Core Vibration | Multicast SCC 150 | Multicast SCC 200 | Multicast SCC 250 | Multicast XL SCC 300 | Multicast XL SCC 360 |

|---|---|---|---|---|---|

| Product Dimensions | 300mm to 1500mm diameter pipes (12" to 60" diameter) and up to 2000mm (78") diameter for manholes | 300mm to 2000mm diameter (12" to 78" diameter) for circular products | 300mm to 2500mm diameter (12" to 96" diameter) | 300mm to 3000mm diameter (12" to 120" diameter) | 600mm to 3600mm diameter (24" to 144" diameter) for circular products |

| Product Lengths | 0,5m to 2,5m (2' to 8'). A model for production of 3,0m (10') long products is available. | 0,5m to 2,5m (2' to 8') A model for production of 3,0m (10') long products is available. | 0,5m to 2,5m (2' to 8') A model for production of 3,0m (10') long products is available. | 0,3m up to 3,0m (1' to 10') | 0,3m up to 3,0m (1' to 10') |

| HawkeyePedershaab VIHY Multicast Vertical Vibration | Multicast SCV 120 | Multicast SCV 150 | Multicast SCV 200 | Multicast SCV 250 | Multicast SCV 300 | Multicast BC 300 | Multicast BC 360 |

|---|---|---|---|---|---|---|---|

| Product Dimensions | 300mm to 1200mm diameter (12" to 48" diameter) for circular products | 300mm to 1500mm diameter (12" to 60" diameter) for circular products | 300mm to 2000mm diameter (12" to 78" diameter) for circular products | 600mm to 2500mm diameter (24" to 96" diameter) for circular products and up to 1800x1800mm (6"x6") | 600mm to 3000mm diameter (24" to 120" diameter) for circular products and up to 2500x2500mm (8"x8") | 2500mm to 2500mm (8" to 8") box culverts and 600mm to 3000mm (24" to 120") diameter for circular products | 3600mm to 3600mm (12" to 12") box culverts and 600mm to 4000mm (24" to 160") diameter for circular products |

| Product Lengths | up to 2,0m (6') | up to 2,0m (6') | up to 2,0m (6') | up to 2,5m (8') | up to 2,5m (8') | up to 2,5m (8') | up to 2,5m (8') |

Key Advantages

Manufacturing and Operational Flexibility

A single machine can make a wide variety of products using processes that are mechanized and controlled from a central operator’s console or from separate controls on the equipment. Multicast can be equipped with manual, semi-automatic or fully automatic controls. Here’s how the process works:

- After the mold is filled, vibrated and pressheaded, an overhead crane is used to offbear the finished product from the machine fully supported in the external jacket.

- The assembly is transported to the curing area and immediately demolded.

- The jacket is then returned to the Multicast for further production.

Multiple Machine Configurations

The Multicast series of machines comprises a comprehensive range of production stations, concrete feeders and vibration systems that allow producers to configure the equipment to their specific requirements. This flexibility provides a cost effective way to start or expand your plant.

Double Station Capability

A Multicast machine can be set up with two production stations each individually configured for the products to be manufactured. Compared to a single station machine, two stations give increased output, increased versatility and greater manufacturing flexibility. An investment in a double station can be made in stages to keep the initial investment low.

Produce Large Diameter Pipes and Manholes

The Multicast machine can make products up to 3.6m (144”) diameter. This allows the producer to respond to the growing need for larger infrastructural products for storm water drainage and storage. In addition, the machine can be supplied with a wide range of handling solutions to ensure efficient production flow of these large products.

Ideal for Lined and Jacking Pipes

Multicast is especially well suited for special applications such as lined pipes and jacking pipes. The machine can be supplied in a special 3m version which is often the preferred product length for jacking pipes. Further, Multicast can be fitted with pneumatic equipment for the production of HDPE, PVC, and GRP-lined concrete pipes. All these features enable concrete producers to offer a wide range of infrastructural products with a single plant.

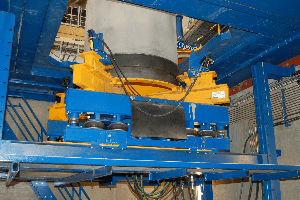

Unique Box Culvert Solutions

Multicast can be equipped with different vibration systems tailormade for the production of box culverts. Vibration tables are available to accommodate up to box culverts as well as synchronized core and jacket vibration systems. Fixed and modular box molds are available. The modular mold and joint ring components can be configured to manufacture boxes of many different sizes with a single set of components.