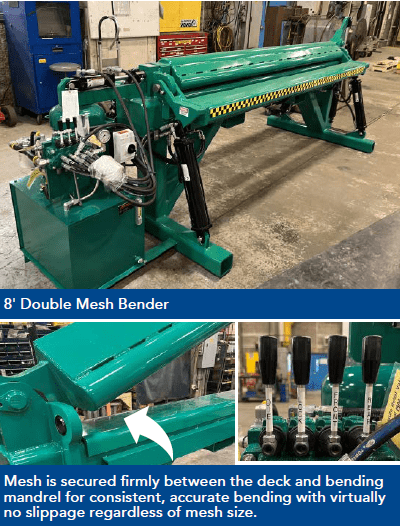

Our Double Direction Mesh Benders were developed in response to the growing precast box culvert market. The standard bender is designed to bend Welded Wire Reinforcing without obstructions in the bending deck through D21 on 2″ spacing or D32 on 4″ spacing.

Double Direction Wire Mesh Bender

Operational Features and Benefits

- Consistent, accurate bending with virtually no slippage regardless of mesh size

- Manual hydraulic controls standard, optional electronic controls

- Loading options from either side

- Unobstructed bending deck

- Performs accurate bends regardless of spacing

- Manually controlled hydraulic locking cylinder

- Optional hands-free operation with remote, electrical foot pedal controls

- Easy cage removal

- Bending capabilities of W21 on 2″ centers (D32 on 4″ centers) to a resting 90°

- 2″ bending radii generally conforms to precast box culverts standard, ASTM C- 1433

- Units available in 8′, 10′, and 12′ lengths

- Available with internal clear space of 102″ (8′), 126″ (10′), and 150″ (12′)

Technical Capabilities

Double Direction Wire Mesh Bender

Double Benders may be loaded from either side. To make the first bend, the Welded Wire Reinforcing mat is placed in position for bending. After securing the mesh between the deck and mandrel, the bending arm is raised and overbends the sheet to form a resting bend of 90°.

To accomplish the second bend, simply move the mesh mat forward (there is no need to raise the mandrel) on the unobstructed bending deck, to the second position. The same method for bending is repeated with the exception that the bend is from the opposite bending arm. After the arm is retracted, the cage will have a “U” configuration.

The cage is extracted from the bender by simply raising the mandrel to the full 90° position. The arm will completely clear the bending deck for easy removal of the cage.

Built with manual hydraulic controls as standard. The operator is in complete command of the machine.

The bending mandrel is safely locked in place by the manually controlled hydraulic locking cylinder. The mandrel is positioned automatically and correctly for each bend.

Standard Features

The following features come standard with our double direction mesh benders.

• Manual Hydraulic controls

• 90° final resting bend

• Heavy tubular construction

• Fork pockets and / or lifting eyes

• Hydraulic hoses are hidden in construction

• Hydraulic cylinders sized and placed for safe, efficient operation

• Bending radii per customer’s specifications (2″ typical for precast box culvert cages)

• Hydraulic cylinders mounted in the bending deck providing unobstructed bending for the full range of (WWR) mesh including D21 on 2″ centers. Or D32 on 4″ centers

• Customer to confirm bending radius and plant voltage at time of purchase

• Standard units available in:

– 8′ width (102″ unobstructed deck space)

– 10′ width (126″ unobstructed deck space)

– 12′ width (150″ unobstructed deck space)

Upgrades

- Electrical remote “hands-free” operation with pedestal and foot pedals