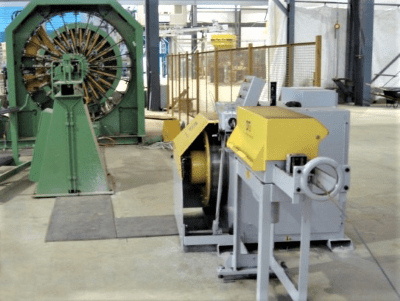

The drive to manufacture better quality concrete products at the least possible cost has brought reinforcement to the forefront. And for good reason-it is one of the major cost components in concrete pipe and other reinforced concrete products. With DTI WireDraw technology, the entire cage can be manufactured from green hot roll rod, the lowest cost material available. Additionally, utilizing inline wiredraw technology with the MBK cage welding machinery smoothes production flow, minimizes material handling, and reduces steel inventory requirements.

Key Advantages

Reduce Labor and Costs

Installing the DTI WireDraw unit directly inline allows it to operate automatically, reducing labor requirements. The unit is configured so that it can be installed directly inline with the cage machine. The green rod is fed directly to the WireDraw unit and the finished drawn wire is automatically fed to the cage machine. While other systems require an operator, the DTI WireDraw unit does not require a manned drawing and re-spooling center.

In addition, the unit eliminates the need to purchase mesh or draw in wire from a secondary source. The DTI WireDraw system works with green hot roll rod that can be purchased directly from the mill, reducing material costs.

Less Material Handling and Inventory

The DTI WireDraw system eliminates the need to store and handle myriad mesh sizes, approximately eight rod sizes will suffice for a typical concrete pipe installation. The circumferential spacing can be varied to meet your required steel area specifications.

Free Up Storage Space

As compared to drawn, hot roll rod can be stored outdoors rather than indoors, freeing up building space for more productive use. For use in automatic cage machines, wire must be free of rust and other contaminants. Drawn wire must be stored inside to protect it. Hot roll rod, however, can be stored outdoors as the rust and mill scale is cleaned from the wire during the inline wire drawing process.

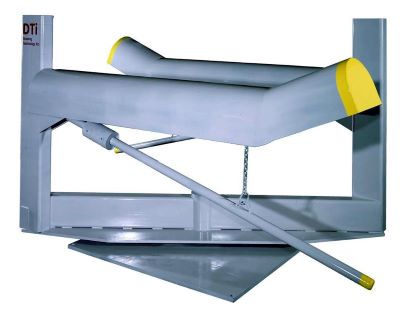

Flipper Payoff Provides Continuous Wire Supply

A twin arm wire payoff allows two coils of wires to be continuously linked for uninterrupted and continuous cage production. The DTI flipper payoff system stores two coils of wires. As the one coil is used up, the tail end is butt welded to the lead end of the second coil. This permits the wire to be continuously loaded and fed to the cage machine for uninterrupted production. The payoff can accommodate two 4,000 lb. coils.

Descaler Cleans Wire

Clean reinforcing wire results in reduced machine wear and maintenance for better operating results and cage quality. Reinforcement wire is descaled and cleaned of all contaminants immediately before the wire enters the CageFlex machine. Clean wire makes for better welding performance, reduces wear, and results in better manufacturing performance of the cage machine.

Turkshead Attachment Deforms Wire

Turkshead attachment allows deformed wire to be used without the need to purchase more expensive material. A turkshead attachment can be installed inline with the WireDraw unit to form deformations in the wire. Deformed reinforcement bonds better to the concrete for improved concrete-to-steel interaction. The use of an inline turkshead permits green hot toll rod to be used for both standard and deformed wire, minimizing material costs.