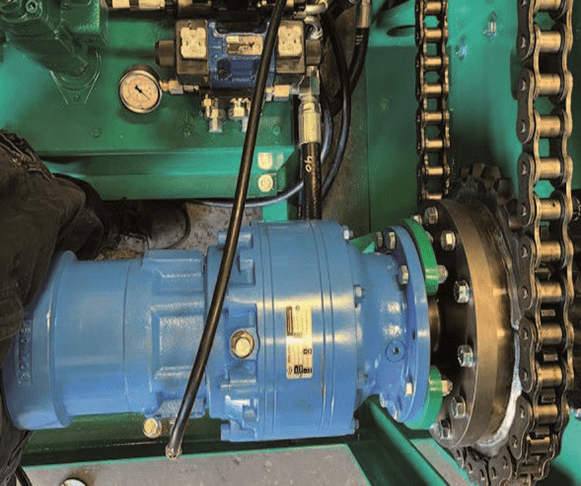

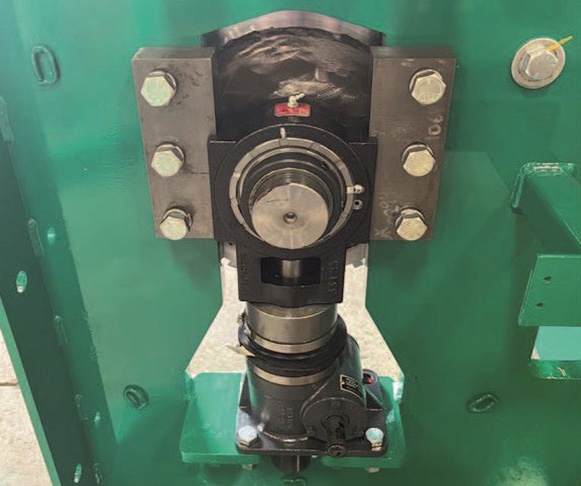

The Hydra-Roll computerized mesh roller is a state-of-the-art machine for the manufacturing of wire pipe cages. Features include the easy load mesh loading system, piloted bearings for ease of operation, an extra large flattening roll for improved traction, and machined grooved rolls for added cage precision.

Operational Features and Benefits

Standard Features

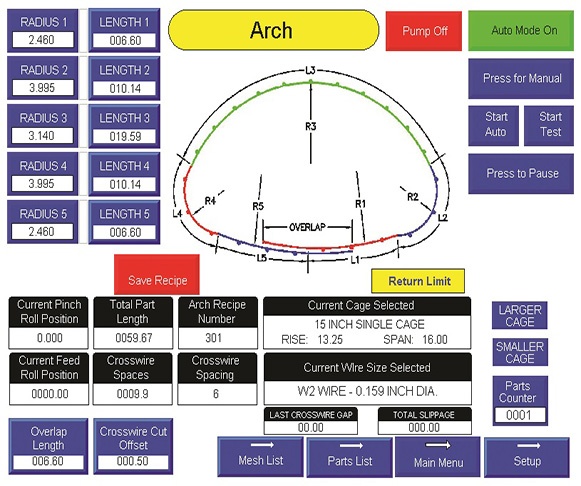

- User friendly, menu-driven computer control system with all recipe files saved to memory.

- 100 selectable custom recipes with name entry allowing operator to make non-standard wire cages or mates.

- One-touch wire cage length and size adjustability calculated by controller.

- Control system monitoring that notifies operator on status of mesh roller, tracks material usage, and when scheduled maintenance is due.

Help screens that include built-in operator’s manual on screen to assist operator. - Emergency stop switches at multiple locations.

- Adjustable cutting location utilizing low maintenance photo electric cross wire sensors.

- “Easy-load” mesh loading system.

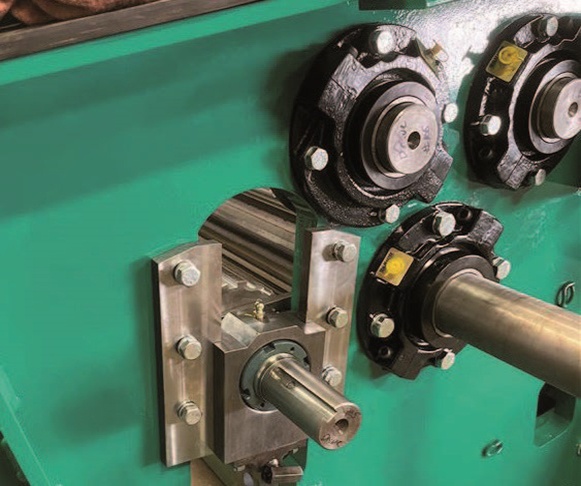

- Large diameter adjustable flattening and traction roller with digital read-out.

- Grooved driven rollers for increased traction.

- Shear blades with multiple cutting edges.

Wire

- Width: 48″–96″

- Size: W2.0 to W12

- Cross Wire Spacing 4″, 6″, and 8″

Preprogrammed Shapes

- Round: 12″–108″ (pipe diameter)

- Elliptical:18″–96″ (equivalent round pipe)

- Arch: 15″–96″ (equivalent round pipe)

- Elliptical/round 18″–96″ (pipe diameter)

- Flat mats: 30″ and longer

- B and C Wall Single and Double Cages

- Cage Tolerance meets ASTM C76

Total Weight

- Mesh Roller 19,500 lbs.

- Payoff Roller 3,600 lbs.

Facility Requirements

- Power: 15 hp 65 Amps @ 230 VAC 3 Phase

- 40 Amps @460 VAC 3 Phase

- 35 Amps @ 575 VAC 3 Phase