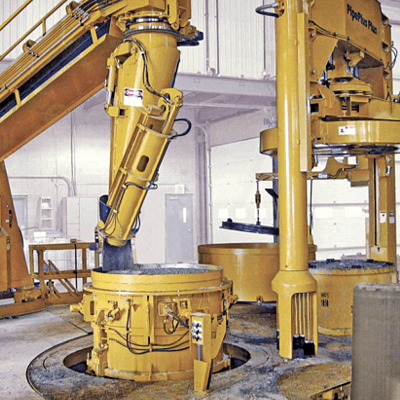

Afinitas brings you a simple, dependable, easy to operate, concrete pipe and manhole machine with its HawkeyePedershaab PipePlus. The PipePlus machine is available with multiform modules and manufactures pipe in numbers that rival more expensive machines. Furthermore, the PipePlus features production flexibility and 10-minute form changeovers, which allows producers to schedule in special orders and keep yard inventories low.

Concrete Products

The PipePlus machine is ideally suited to produce:

Capacity

Depending on the machine model, a typical HawkeyePedershaab PipePlus plant offers an annual production capacity of 60,000-70,000 tons of product in a one-shift operation.

Models

- HawkeyePedershaab PipePlusPlus

- HawkeyePedershaab PipePlus 96

- HawkeyePedershaab PipePlusPlus Compact

Other models available upon request.

| HawkeyePedershaab PipePlus | PipePlusPlus | PipePlus 96 | PipePlusPlus Compact |

|---|---|---|---|

| Product Dimensions | 300mm to 1800mm diameter (12" to 72" diameter) | 300mm to 2400mm diameter (12" to 96" diameter) | 300mm to 1800mm diameter (12" to 72" diameter). |

| Product Lengths | up to 3.5M (12') | up to 3.5M (12') | up to 3.5M (12') |

| Maximum Multiforms by Machine | |||

| Singleform | up to 72" diameter | up to 96" diameter | up to 72" on one station and 60" on other two stations |

| Duoform | up to 30" diameter | up to 48" diameter | up to 24" diameter |

| Triform | up to 36" diameter | ||

| Quadform | up to 18" diameter | up to 30" diameter | up to 18" diameter |

| SixPak | up to 24" diameter | ||

| EightPak | up to 18" diameter | ||

PipePlus Machine Key Advantages

Simple Operation and Maintenance

Afinitas understands the need for efficiency in your operations. For this reason, we use off-the-shelf components wherever possible to make the PipePlusPlus easy to run and maintain. Here’s how it works:

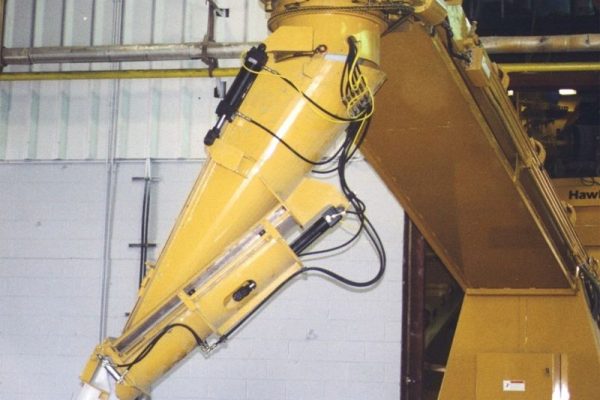

- A concrete distributor chute automatically adjusts to the form size in the fill station and begins to feed concrete into the form.

- The feed rates and vibration settings are stored in the PLC for each product type (manual control also available).

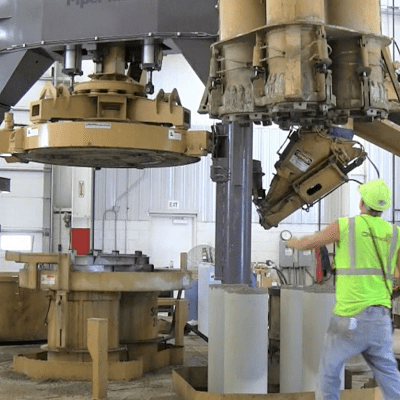

- After the tongue former is placed in the filled form set, the PipePlusPlus pressheading cycle automatically commences.

- The presshead presses the tongue former to form the spigot, trowels the joint surface, and returns to the home position for the next pipe.

- For added flexibility, concrete pipes can be offborne from the PipePlusPlus machine with an automatic or conventional overhead crane.

High Productivity, Flexibility and Versatility

Expanded Output with PipePlus Multiforms

Quick Form Changeover

High Concrete Product Quality

With the PipePlus machine you have variable feed rates and vibration settings specific to each product type to ensure a quality product no matter what is being made. In addition, the PipePlus pressheading system utilizes stay-in-place headers for smooth, dimensionally accurate spigots every time.

Upgrade Your PipePlus with Ease

Our PipePlusPlus Compact model makes it simple to replace your existing PipePlus machine. In fact, it fits into your existing pit and utilizes your existing form and joint rings. Even better, PipePlusPlus Compact features new, advanced control technology and machine upgrades that will boost your productivity, including:

- A free-standing control console with a programmable logic controller that provides complete command over all operations.

- Advanced electro-hydraulic and pneumatic controllers for push-button operation.

- Automatic pressureheading.

- Semi-automatic filling with computer-controlled feeding.

- Articulated header placement jib with an enlarged swing radius to pick headers from three stacks and allow an oil dip tank to be incorporated into the system.