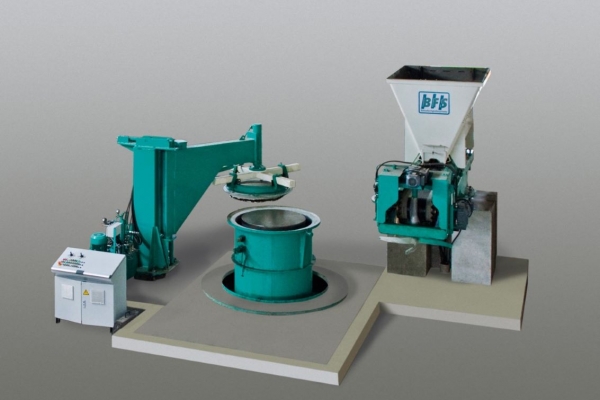

Afinitas offers this modular BFS Universal system as an ideal choice for rapidly growing precast concrete markets, as it can be expanded gradually, whenever necessary. Consequently, production can begin with a modest investment and, as demands increase, BFS equipment can be added to build a highly productive plant. Even in its most basic configuration, the BFS Universal guarantees the highest levels of concrete product quality.

Concrete Products

The BFS Universal machine is ideally suited to produce:

| BFS Universal | Riser Products | Cone Products | Square Products |

|---|---|---|---|

| Product Diameters | 800-1500mm (60") | 800-1200mm (50") | up to 1000x1000mm (40"x40") |

| Product Lengths | up to 1300mm (50") |

BFS Universal Machine Key Advantages

BFS Universal is Easy to Maintain

The BFS Universal is engineered to be almost maintenance-free. Universal is designed with a sturdy, rigid construction that consists of the following parts:

- Concrete Feeding Unit

- Mold equipment and Accessories

- Hydraulic Unit

- Electric Control System

- Pressing Arm

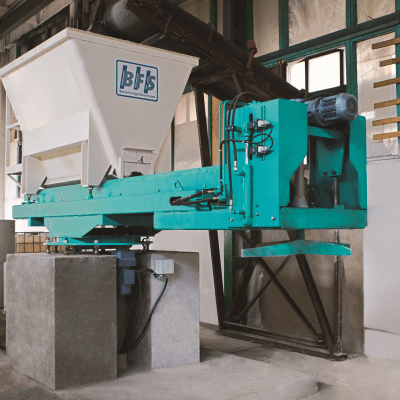

Efficient Feeding

The BFS Universal’s concrete feeding unit operates using a conveyor belt with a concrete holding hopper. The unit has a base frame for mounting on the floor with a ball bearing. In addition, the feeding unit swivels manually using a conveyor belt drive that is equipped with an electronic control system.

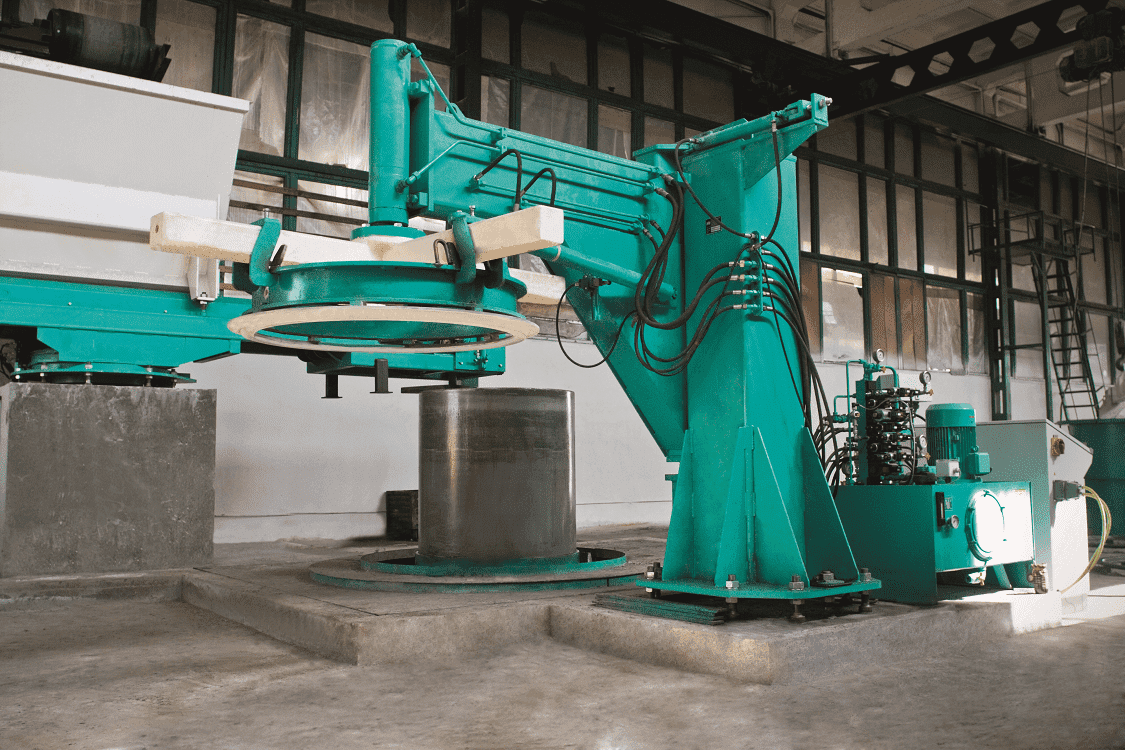

Hydraulic Press Arm

The BFS Universal’s main frame has a mounted press arm, with a hydraulically powered swivel motion. Universal uses a mounted spigot former presshead, with a mounted press turning gear for the spigot forming ring, and a presshead mounting bracket.

Robust Mold Equipment

The BFS Universal system features an inner mold and outer mold with accessories and a lifting beam that is useful for concrete product handling. The Universal is designed with a vibrating system with central vibrators that are mounted in the mold core. A frequency converter can be added as an option.

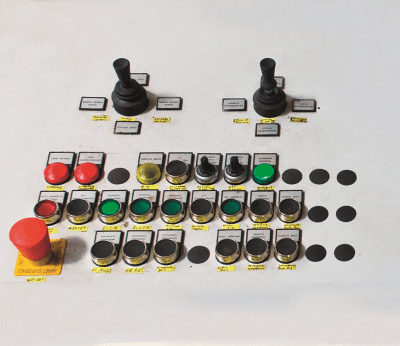

BFS Universal Electric Controls

The Universal’s electric control system for the manual control of the press arm is designed for 230/400 V, 50 Hz.