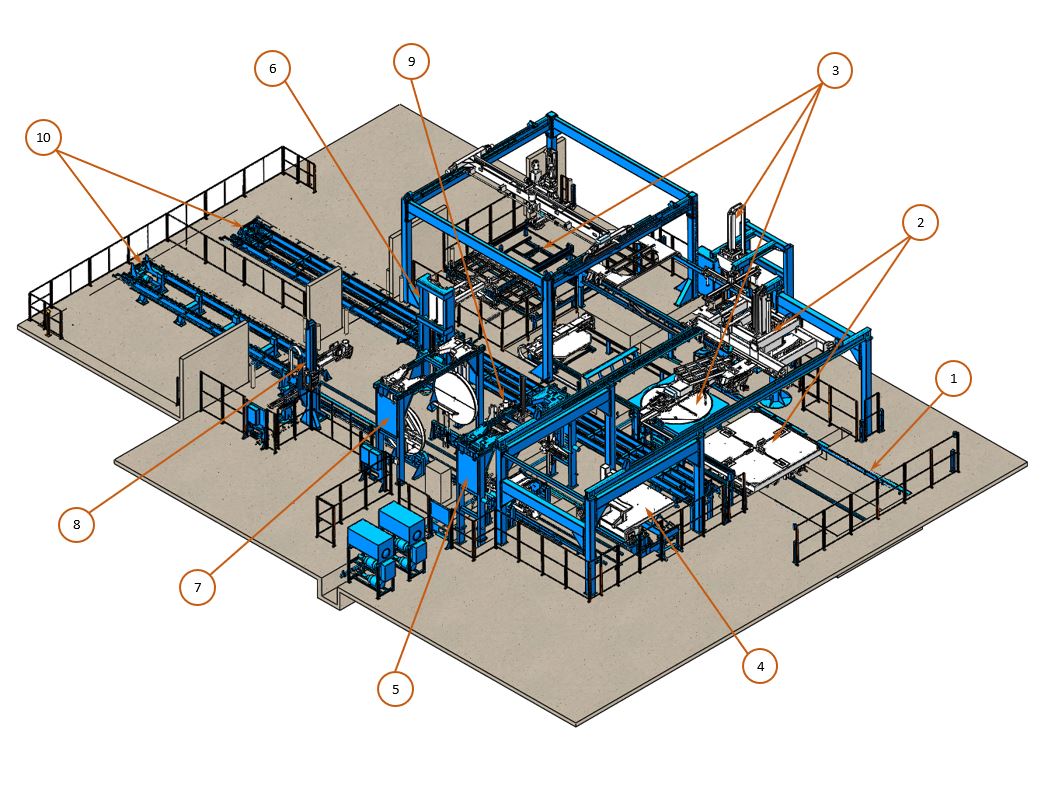

VROC Handling equipment automates the removal of the pallet and header from the finished product, stacks the joint rings, and places the product on a conveyor for further processing or transport outdoors. Modules are available for automatic deburring, marking, vacuum testing, joint ring cleaning, storage and retrieval. VROC handling equipment is designed for 12” (300mm) to 72” (1800mm) pipe and can be fully integrated into new pipe plants or added to existing pipe facilities as an independent system.

1. Transport

Cured pipe are transported to the VROC depalletizing station. Pipe can be automatically transported with a manipulator or vertically carried with a forklift truck.

2. Joint Ring Removal

An overhead manipulator clamps the pipe and simultaneously secures the header. With a combination of lifting and pneumatic tapping, the pallet and header are removed. The removed joint rings are automatically fed to cleaners. The pipe is transported to a tipper and a post-processing line.

3. Pallet Cleaning, Storage, and Retrieval

The removed pallets are cleaned by a dedicated pallet cleaner. The cleaned pallets are picked and placed into a storage and retrieval area. Pallets are stored and await either automatic or manual retrieval. Pallets can also be stacked on handling skids for manual transport to the pipe machine or external storage.

3. Header Cleaning, Storage, and Retrieval

The removed headers are cleaned by a dedicated header cleaner. The cleaned headers are picked and placed into a storage and retrieval area. Headers are stored and await either automatic or manual retrieval. Headers can also be stacked on handling skids for manual transport to the pipe machine or external storage.

4. Tipping

After the pallet and header are removed the overhead manipulator may place the pipe on the manhole conveyor or in a tipper. If placed in the tipper, the tipped pipe is now ready for post-processing. The processing system automatically adjusts to different pipe diameters as they enter the system. Powered shuttles transport the pipe to the various processing stations.

5. Deburring

The bell and spigot end of the pipe are automatically deburred. Rotating cones debur both the inner and outer edges of the pipe. Deburrers automatically adjust to the pipe diameter entering the system.

6. Manhole Deburring

The spigot end of the pipe is automatically deburred. Rotating cones debur the inner and outer edges of the pipe. Deburrers automatically adjust to the pipe diameter entering the system.

7. Vacuum Testing

Pipe are vacuum tested. Two closed cell neoprene coated platens press into the ends of the pipe and a vacuum is drawn. Vacuum is held for a preset time and pressure. If the pipe passes the vacuum test, the platens automatically release. Otherwise, an alarm sounds. Results are measured and recorded.

8. Marking

The barrel of the pipe is marked with an inkjet printer. Both internal and external markers are available. Markings can include pipe size and class, date of manufacture, vacuum test, and manufacturer’s name and logo.

9. Manhole Marking

The barrel of the pipe is marked with an inkjet printer. Markings can include pipe size and class, date of manufacture, vacuum test, and manufacturer’s name and logo.

10. Pipe Exit/Sorter

An outfeed conveyor or a manhole conveyor transport the completed pipe outdoors for yarding. The outfeed conveyor system can be equipped with a sorter and up to three outdoor storage lines. The automatic sorter directs pipe of a given size to each storage line so that like pipe can be easily picked in multiples and transported to the storage yard.