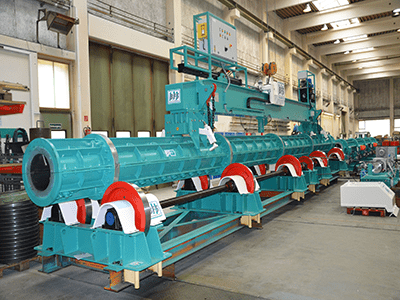

Afinitas company BFS is known for its specially developed spun concrete technologies that enable the production of reinforced or prestressed concrete poles and piles that are fully compliant with local regulations. The wide range of equipment offered by BFS fulfills all requirements regarding production cycles; from concrete formulation and mixing to spinning, drying, demoulding, manufacture of reinforcement cages, prestressing and testing. The use of biconical moulds enables significantly increased productivity as two products can be spun in each cycle. The degree of automation can be adapted to your needs in terms of productivity and flexibility.

Concrete Products

Our BFS spun concrete technologies allow you to produce a variety of products, including:

Standard Prestressed Reinforced Poles

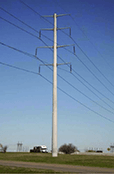

The high quality obtained by the spinning process allows production of ordinary reinforced concrete poles mainly for electrical lines but also for telephone lines. According to local standards or when the requirements are both for high tip loads and light poles, the prestressed reinforced concrete poles are most commonly used.

Ornamental – Decorative Spun Pole

The use of ornamental spun poles is a growing area thanks to various environment preservation requirements. BFS equipment can help produce the appropriate materials and shapes specified by architects and landscape professionals. The BFS team is experienced in supplying the special moulds needed for manufacturing decorative poles of any shape using the spinning process.

Concrete Telecommunications Towers

The high quality obtained by the spinning process allows the production of communications towers up to 45 meters (148′) or more if needed for project requirements.

Precast Concrete Spun Piles Technology

This technology is used in applications fo oil reinforcement, building foundations, offshore/onshore maritime structures, prestressed or normal reinforced concrete of 6-50 m length and size from 150mm up to 2000mm diameter.

- Tapered piles single piece

- Cylindrical piles single piece

- Cylindrical piles jointed type

- Square, octagon piles jointed type

- Micropiles, H piles

Sizes of piles up to 800 mm diameter use the same equipment shown for poles production. Particular designed equipment are suitable to cover the production process of larger sizes (up to 2000 mm diameter).

Interested in Vibrated and Spun Poles, Piles or Columns?

Email: Choukri Karabach (Product Line Leader) or call

+49 175 2201559

Key Advantages

BFS Advanced Spun Pole Technology

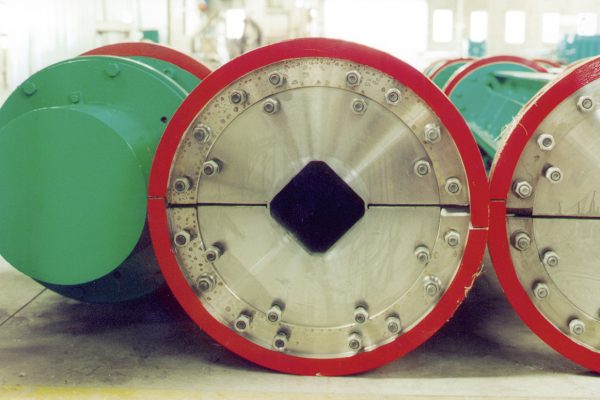

BFS has more than 50 years of experience in this field, producing state-of- the-art centrifugal spinning equipment. BFS Spun Pole Technology is used for a variety of applications, including power cable poles, GPS poles, mobile phone poles, light masts and billboard poles (parking garages and malls), and street lanterns. The use of biconical moulds enables significantly increased productivity as two products or more can be spun in each cycle. The degree of automation can be adapted to your needs in terms of productivity and flexibility.

- Production range from 300-800mm (12-32″) outer diameter

- From 6 up to 50m (20-164′) length in a single piece

- Bioconical moulds for two pieces or more per mould

- PLC controlled spinning process

- Quick opening and closing procedures for moulds

- Fast concrete filling system

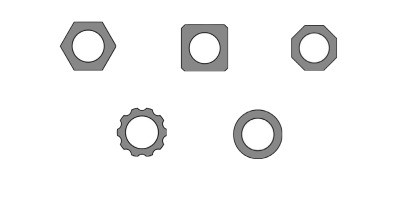

- Variety of shaped possibilities for tapered poles: circular, square, hexagon, octogon, fluted, flared, decorative shape on any regular geometric section

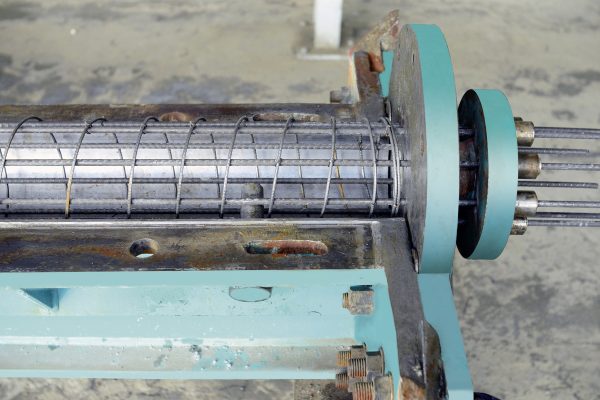

BFS Spun Piles Technology

Precast concrete spun piles are used for soil reinforcement, building foundations, offshore/onshore maritime structures, among other applications. Our manufacturing covers products that range:

- From 150mm up to 2000 (6″ to 80″) diameter

- From 6 to 50m (20′ to 164″) length

- Prestressed or reinforced

- Tapered end or cylindrical single piece piles

- Cylindrical jointed type piles

- Square/octogon piles jointed type

- Micro piles, H piles

BFS Vibration Technology

The BFS system also allows for concrete columns, poles and piles to be produced by vibration methods to meet specific requirements.

P.S.C. Pole Shapes

Spun Process

The Spun Pole Product Cycle

Vibrated Process

The Vibrated Pole Product Process