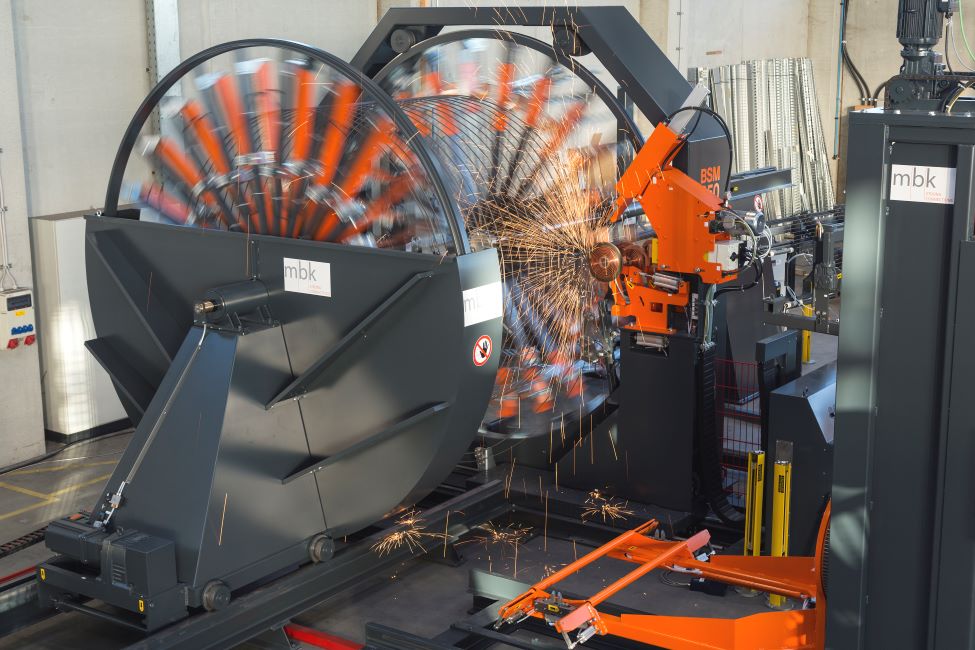

When it comes to reinforcement cage machinery for manholes and concrete pipes, Afinitas trusts the expert: MBK. We have been partnering with MBK since 1990, and today we are proud to be their exclusive North American distributor for leading-edge reinforcement cage equipment. MBK’s streamlined operating design simplifies the cage-making process, reduces machine maintenance, and provides dependable day-to-day operations. You’ll find many advantages to choosing MBK cage welding machinery, including:

- The cost of hot roll rod is considerably less than mesh.

- Reduction in steel inventory as the MBK can use common wire sizes with various wire spacings to achieve different steel areas.

- Over-steeling is reduced.

- Uses precut longitudinals to simplify machine design and eliminate the need for multiple coil reels.

- Cages set straight and true on the pallet.

- Fast changeover time.

- Mounts directly to existing concrete floor, no machine foundation required.

- Floor area not required for individual longitudinal wire spools.

- Inline wire drawing with no additional personnel is possible as the circumferential wire is fed directly into the MBK.

- Can be equipped to produce elliptical as well as round cages.