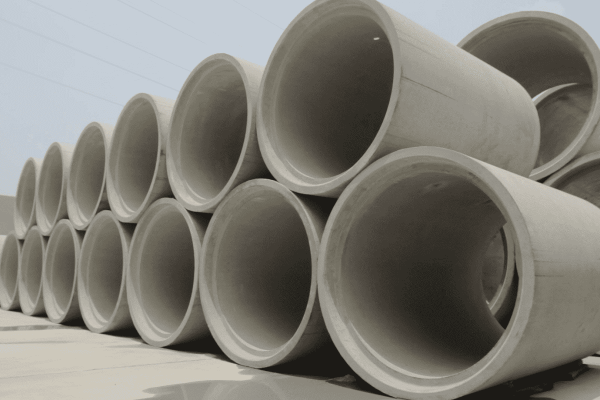

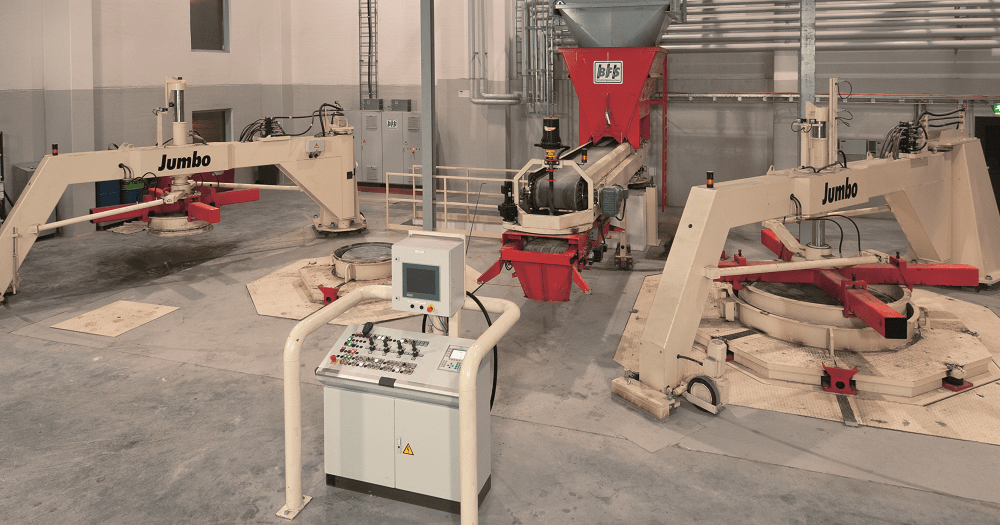

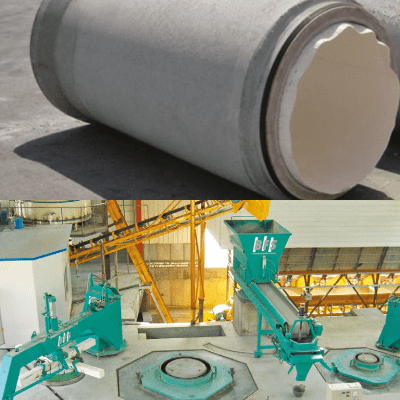

Afinitas knows a versatile piece of a equipment can be invaluable to your operations. That’s why the BFS Jumbo has become a trusted machine for the production of reinforced and non-reinforced concrete pipes and manholes up to 4000mm (12′) diameter. In addition, the Jumbo also produces manhole products such as manhole rings and base units.

Concrete Products

The Jumbo can produce almost any infrastructural product, including:

Capacity

Depending on the machine model, configuration, and the products being manufactured, the Jumbo can produce from 35,000 to 100,000 tons of product annually.

Models

- Jumbo RL1500

- Jumbo R2000

- Jumbo R2500

- Jumbo R3000

- Jumbo R3600

- Jumbo R4000

| BFS Jumbo | BFS Jumbo RL1500 | BFS Jumbo R2000 | BFS Jumbo R2500 | BFS Jumbo R3000 | BFS Jumbo R3600 | BFS Jumbo R4000 |

|---|---|---|---|---|---|---|

| Product Dimensions | 300mm (12") to 1500mm ( 60") diameter pipe 1100mm x 1100mm (42"x 42") max. square 700mm x 1400mm (32" x 56") max. rectangular | 300mm (12") to 2000mm ( 78") diameter pipe 1500mm x 1500mm (60"x 60") max. square 900mm x 1800mm (36" x 72") max. rectangular | 300mm (12") to 2500mm ( 98") diameter pipe 2000mm x 2000mm (78"x 78") max. square 1200mm x 2400mm (48" x 96") max. rectangular | 300mm (12") to 3000mm ( 120") diameter pipe 2500mm x 2500mm 98"x 98") max. square 1600mm x 3000mm (64" x 120") max. rectangular | 300mm (12") to 3600mm ( 142") diameter pipe 3000mm x 3000mm (120"x 120") max. square 1800mm x 3400mm (72" x134") max. rectangular | 300mm (12") to 4000mm (156") diameter pipe 3400mm x 3400mm (134"x 134") max. square 2800mm x 3800mm (112" x 150") max. rectangular |

| Product Lengths | up to 4000m (40') | up to 4000m (40') | up to 4000m (40') | up to 4000m (40') | up to 4000m (40') | up to 4000m (40') |

BFS Jumbo Machine Key Advantages

High Quality Concrete Products in All Sizes

While the BFS Jumbo is ideal for producing reinforced and non-reinforced concrete pipe, the machine also allows for quick changeovers to produce almost any concrete product. Here’s a brief overview of how the Jumbo system is able to maintain consistent levels of quality no matter the product size.

- The rotating concrete feeding unit of the Jumbo together with rotating distribution conveyor belt efficiently transports concrete into the mold.

- A frequency-controlled drive handles the uniform filling of the concrete to ensure optimal distribution for the specific concrete products being produced.

- A central vibrator that contains several vibrator units, depending on concrete pipe length, gives intensive and continuous compaction.

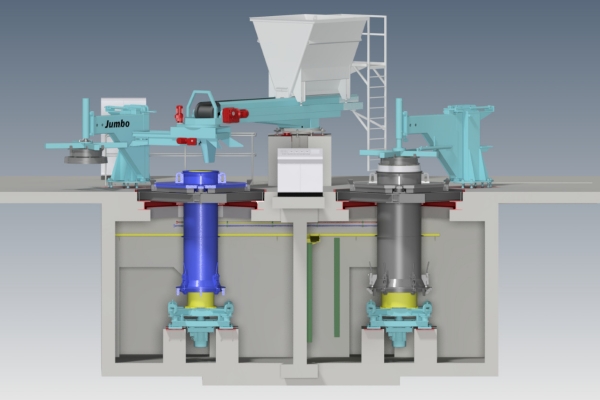

Powerful Central Vibration

There are many advantages to Jumbo’s multi-level central vibration system, including:

- Hydraulic-quick-clamping system in every vibrator for fast conversion

- Modular construction system for vibrator units for production of different concrete pipe lengths and optimal adaptability to the products

- Generously calculated vibration forces and a standard number of revolutions of 4200 rpm guarantee intensive concrete compaction

- Additionally equipped with a frequency converter or a frequency regulator for optimizing the concrete quality

- Maintenance-friendly grease lubrication makes the process easy, reliable and problem-free

- Vibration cross: rigid with quick clamping system

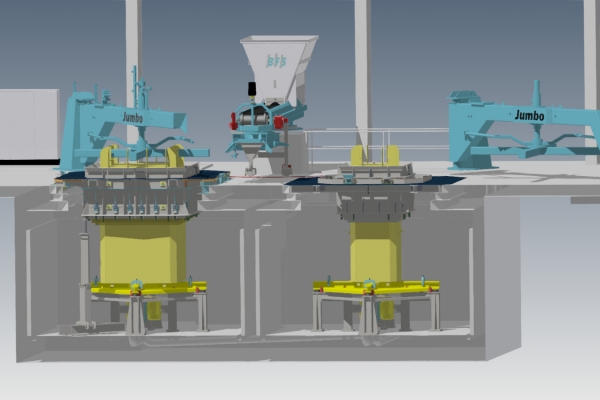

BFS Concrete Feeding System Options

- Feeder with rotating feeder belt is a standard concrete feeding system available with CNC feeding track control, laser filling system and remote control

- Feeder filling system with filling box and rotating distributor star. This system is for manhole base and septic tank rings that are fast filling without a cage.

- Combi-feeder with cross movement. This is an exchangeable filling system filling box and rotating belt.

- Feeding unit with rotating chute and scraper.

- Feeder with height-adjustable distributor star designed for manhole and manhole base production.

Quick Changeovers with Jumbo

BFS Jumbo change-overs to concrete elements in different lengths can be accomplished in minutes utilizing a lifting frame with stable guiding columns and quick connectors to enable fast height adjustment.

- Quick clamping device for inner mold/vibrating cross

- Spigot former quick release

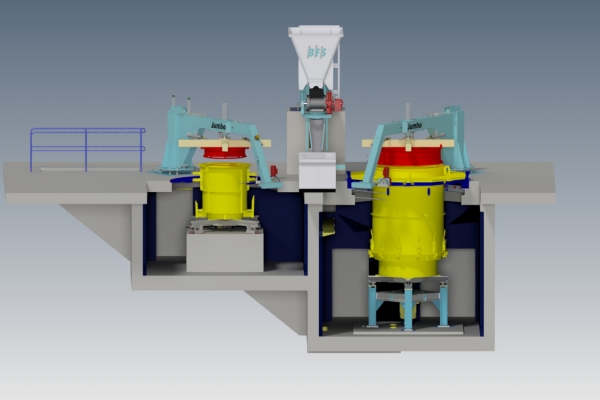

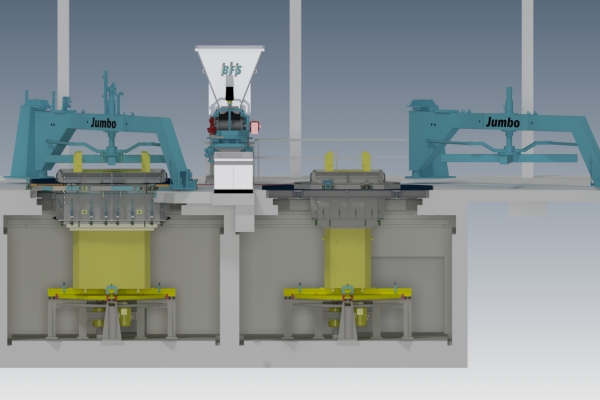

Manufacturing Options – BFS Jumbo Liner, BFS Jumbo Duo

Our Jumbo Liner system enables the production of PVC and HDPE-lined products, while Jumbo Duo combines the power of two Jumbos into one system for maximum production output. Furthermore, with Jumbo Duo you can produce two different products simultaneously, optimizing your daily output.

Afinitas helps add more technology to meet your requirements:

Lifting, Tilting

Afinitas’s BFS brand offers many options, including:

- Tilting device for base production

- Lifting beam for double pit production

- Single beam

- Cross beam for big products

- Single beam yoke with hydraulic load center adjustment (U-culvert production)

- Hydraulic pipe claming and tilting device

Jumbo-Finitec

See More BFS Jumbo Machines