In 1956, an idea came to the mind of H.H. “Hank” Schmidgall as he struggled to find an economic and simple way to unload concrete pipe produced from his small factory in Morning Sun, Iowa, from the back of a truck. The idea blossomed into the Pipemaster Pipe Unloader. Today, thousands of concrete pipe unloaders later, the Pipemaster is still the industry standard method of unloading concrete pipe from the back of a flatbed truck.

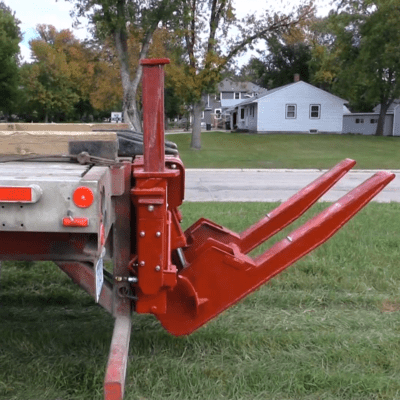

Afinitas offers the Pipemaster Pipe Unloader from HawkeyePedershaab, an efficient, safer, and dependable way to unload concrete pipe. This concrete pipe unloading equipment has a smooth hydraulic action that virtually eliminates pipe breakage. Pipe can be unloaded almost as fast as they can be rolled off the truck. And it’s economical. The Pipemaster is completely self-contained and requires no external power source. Its rugged construction makes for years of trouble-free pipe unloading.

Learn more about the HawkeyePedershaab pipe unloading equipment offered by Afinitas by contacting sales rep today!

Pipemaster Concrete Pipe Unloader Key Advantages

Eliminate Jobsite Delays

With Pipemaster concrete pipe unloaders, the truck driver can unload the pipe. There’s no need to wait for the contractor.The jobsite can be a very busy place. The contractor may have his equipment tied up installing pipe or in a location away from where pipe is being delivered. The Pipemaster solves those logistical problems contractors face by allowing the driver to unload the pipe. There’s no need to wait on the contractor’s equipment.

Wide Unloading Range for Concrete Pipe

The Pipemaster unloads nearly all the concrete pipe sizes produced by the average plant. Models are available to unload concrete pipe weighing as little as 100 lbs. (45kg) up to pipe as large as 20,600 lbs. (9344kg) and pipe up to 96” (2400mm) diameter. Special models are also available for drop deck trailers.

Easy Operation and Maintenance

The Pipemaster is very easy to use. By setting one simple control, concrete pipes are just rolled to the pipe unloader and automatically unloaded.One control sets the hydraulic system of the Pipemaster to unload any size of concrete pipe within the capacity of the concrete pipe unloader. Just roll the pipe to the forks of the unloader. Then the Pipemaster automatically unloads the pipe and resets for the next pipe. There are no external power sources or hydraulic pumps to operate and maintain. The Pipemaster unloader utilizes hydraulic resistance to unload concrete pipe with complete control.

No External Power Supply Required

Pipemaster utilizes hydraulic resistance to unload concrete pipe. This unique design requires no external hydraulic power. As a result, the Pipemaster can be easily used on any trailer equipped with a mounting rack. The Pipemaster’s hydraulic operating system simplifies maintenance and operation and withstands the rigors of concrete pipe transport and unloading.

Pipemaster Repair Service

Rest assured your HawkeyePedershaab Pipemaster was built to last. However, after decades of use, there are parts that will need to be replaced. If you are not sure how old your Pipemaster is, just find the machine’s serial number, take the first two digits and then subtract 5. That tells you the year it was made. We have rebuilt machines dating back to the early 1960s and have returned them to like-new condition with updated options and upgrades. Our HawkeyePedershaab Parts Team can even turn a Pipemaster SM100 into a Pipemaster IM2100. It is worth noting that most rebuilds come in at one-third to one-half the cost of a new Pipemaster and will likely remain in service for decades to come. Contact us at hawkeyeparts@hpct.com to get a time and cost estimate to rebuild your Pipemaster. We look forward to helping you get your Pipemaster operating in the way it was designed to!

NEW! Series 3000 Pipemaster Concrete Pipe Unloader

New Series 3000 Pipemaster

To enhance the operation, performance, and safety of the Pipemaster Concrete Pipe Unloader, the new Series 3000 Pipemaster has been developed. This pipe unloader features the following new design benefits as compared to the original Series of concrete pipe unloaders:

-

Supplemental Safety Barrier

To help prevent pipe from accidentally rolling off the rear of the trailer when the forks are in the lowered position, this concrete pipe unloader has a safety barrier that automatically rises above the trailer bed as the forks lower during unloading.

-

New 50% Wider Forks

The new 3000 Series Pipemaster Pipe Unloader provides an increased stance of unloading forks permits for more secure unloading of pipe. This feature is applicable for the Model 3100 pipe unloader only.

-

Easy Air Removal

As concrete pipes are unloaded, a vacuum is created within the Pipemaster’s dash pot hydraulic system which can tend to draw air into the system. A dome is incorporated into the hydraulic circuit of the pipe unloader to collect entrapped air. A single, easy-to-reach push-button allows air to be easily expelled from the system. If system bleeding is required due to a broken hose or low oil condition, all bleeder petcocks are accessible with the unloader on the trailer.

-

New Manifold Technology

The new 3000 Series Pipemaster Concrete Pipe Unloader’s manifold technology simplifies the hydraulic system, eliminating several hoses and hydraulic joints.

-

Increased Oil Capacity

The oil capacity of the hydraulic circuit has been increased permitting longer maintenance intervals.

-

Visual Oil Gauge

A visual sight gauge permits the oil level to be checked without removing the pipe unloader’s inspection cover plate. This feature is available for the Model 3206 pipe unloader only.

The new Series 3000 Pipemaster Concrete Pipe Unloader is now being shipped in place of the previous Model 2100 and 2206 unloaders. The Series 3000 Pipemaster directly mounts to your existing IM Mounting Racks and most of the machine parts are interchangeable with the previous models.