Production system for wetcast concrete slabs, veneers and other special concrete products

Prima Scape draws upon decades of vibration technology to help you create visually appealing and mechanically precise slabs, pavers, veneers and more. With one automated system, create reproductions of natural stones, slate, granite or terracotta in exact laying units for flooring, pool and fountain slabs, patios, deck slabs and other residential and commercial applications.

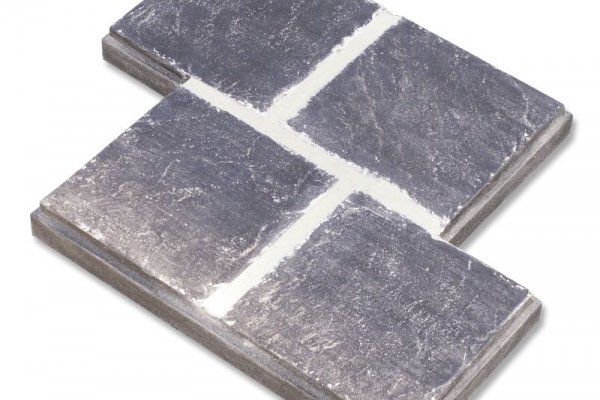

Concrete Products

Prima Scape is ideally suited to produce:

Slab

Veneer

Special Products

Typical Prima Scape Line for Regular Slabs

Dosing Techniques

Prima Scape allows you to perform dosing by either weight or volume (depending on your specific needs) with reliable accuracy.

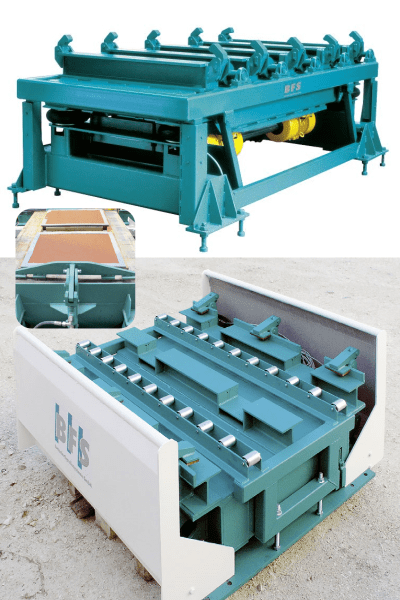

Perfect Compaction with Prima Scape

Prima Scape is known worldwide for its vibrating technologys equipment that can be customized to your dimensions and requirements. The system uses a hydraulic clamping device and precise leveling system optimized by FFM calculation programs.

The process ensures efficient production of individual products as the individual molds are fixed on standardized pallets which are moved by roller conveyors, crane robots or handling systems to the vibration table. Individual vibrating programs are applied to each specific product for optimal concrete compaction. It’s an economical way to produce many types of products in the highest quality.

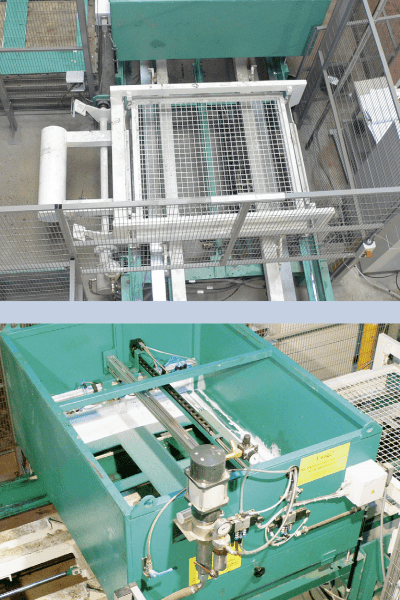

Quick Cleaning – Accurate Spraying

Our innovative design allows you to clean the mold without slowing down production while also preparing for the next step in production.

Mold Cleaning

Our process makes it simple. Because the filling of the molds is so precise, extra concrete waste granules or pellets are automatically removed during the running process.

Release Spraying

Our specially designed spraying pistols with adjustable spraying directions (optional) ensure exact spraying in the mold. In addition, an exhaust system housing can be added for the hole spraying unit to eliminate fog or mist from forming around the mold.

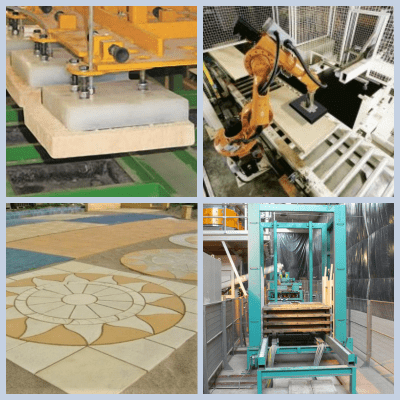

Other Prima Scape Features

- Automated demolding system

- Surface coating systems

- Slab turner

- Mold cleaning station

- Packing station

- Option for separate wet and dry line

- Automated packing unit

- Robotic stacking unit

Special Product Production

Scroll through the flexible modules that accommodate a variety of molds, designs, dimensions and materials.