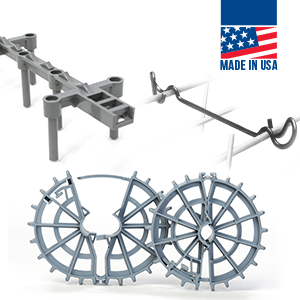

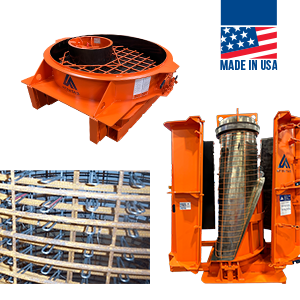

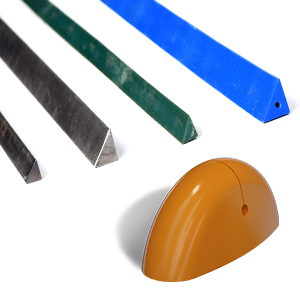

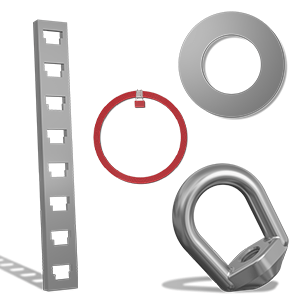

When you team up with Afinitas you get product, sourcing, manufacturing and service specialists who know accessories and know how they are used. Afinitas brings you the highest quality products, many of which are MADE in the USA, steel and plastic precast concrete reinforcement spacers, steel stirrup mats, rebar mats, pipe ties-tie rods, cone and flared-end cages, drainage grates, trash guards and other fabricated steel products, lifting devices, fixation products, utility box hardware and many more accessories. With product expertise and distribution centers located throughout North America and the UK, Afinitas is the partner to rely on to ensure you have the right solution for your application, when and where you need it.

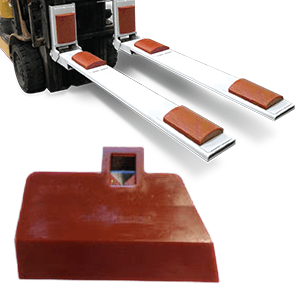

Concrete Accessories

Service, Selection, Solutions for Your Precast Concrete Accessory Needs

Featured Products

More from Afinitas

Steel Fabrication Contract Manufacturing

Learn MoreSee our Forming Systems

Learn MoreLooking for durable formwork?

Afinitas offers formwork systems that are built to last.